The PVC WPC panel making machine is contrary to the way you can do a great deal of panels in an exceedingly short period of time. This machine is popular within the industry simply because it saves time and money on panel making. This allows companies to manufacture more panels per unit time and is excellent for business.

The fact that the PVC WPC panel making machine manufactures robust and quality panels is one them. Made to endure wear and tear through the years, these panels have been designed for a range of applications. When companies are using these panels, then they can rest assured that they have a product in their hands which is reliable and strong.

This PVC WPC panel making machine is used to produce high-quality PET bottle flakes. Again - the whole process is sped up and made much more efficient, which means factories can build many, many of these panels at a faster clip than before. For some businesses that must produce enough to meet demand, this uptick in efficiency is essential.

This machine is also user friendly. It is easy to operate and can be worked with by anyone who has been properly trained. It also helps in the smooth functioning of machines because workers who need to run this machine can be any worker, they not limited for experts. It is an indispensable tool that makes high-quality panels according to industry requirements.

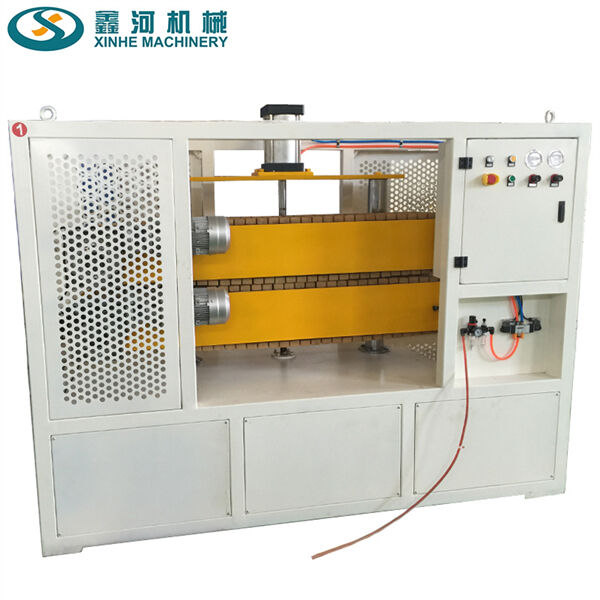

They are advanced PVC WPC panel machines which have been designed to enable manufacturers and factories produce a large volume of panels within the shortest possible time. This is especially handy for places which might need heaps and heaps of panels at once, like construction sites or manufacturing plants. This allows companies to maintain regular deliveries of their products without interruptions.

One of the best things about this PVC WPC panel making machine is that it requires very minimum maintenance. So, this means it is quite durable and can be used for a long period without any repairs or replacements. As a result, it is the best option for those who plan to save in the long run. Less maintenance, more time for production which is imperative to any business.

PVC WPC wall panel production line is not only high efficiency and save cost, but also the follow-up market give a good expectation. Meanwhile, this can also be altered and personalized according to the different requirements of varying businesses. This is why it serves as a reliable tool in numerous sectors ranging from construction to that of wooden furniture-making.

Pre-Sales: Our sales team with more than five years of experience, will recommend the most suitable machine configuration for you. We offer customer support 24 hours a day and factory tours with video.In-Sales: Our videos illustrate the manufacturing process starting from raw steel to the finished products.After-Sales: Our engineers offer on-site support for a pvc wpc panel making machine and lifetime video technical support starting from raw materials through to the final product.

At Jiangsu Xinhe we adhere to stringent standards regarding the thickness and materials of machine steel and provide the most areas that are at risk pvc wpc panel making machine safety measures our production lines offer long life span with low failure rates and a stable efficient production Many of our customers have been using their machines for more then 8 years

We offer customized machines in terms of size, color and automation. Molds are customizable in accordance with what the final product is expected to look like. We've evolved from pvc wpc panel making machine and have become one of the top 10 Chinese extrusion lines made of plastic.

Our machines are configured to meet the demands of the client We offer factory-direct sales high-quality items as well as an extensive after-sales support Our machines have a lifespan that pvc wpc panel making machine 8 years They have been well-received by our customers from Vietnam Indonesia Saudi Arabia South Africa Bolivia as well as other regions

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights Reserved