The wall panel machine helps in making walls for buildings. That is why construction has become easier than before. Today, we will share with you the fantastic wall panel machine and how this combined heat storage and production system produces cool effects for builders and architects.

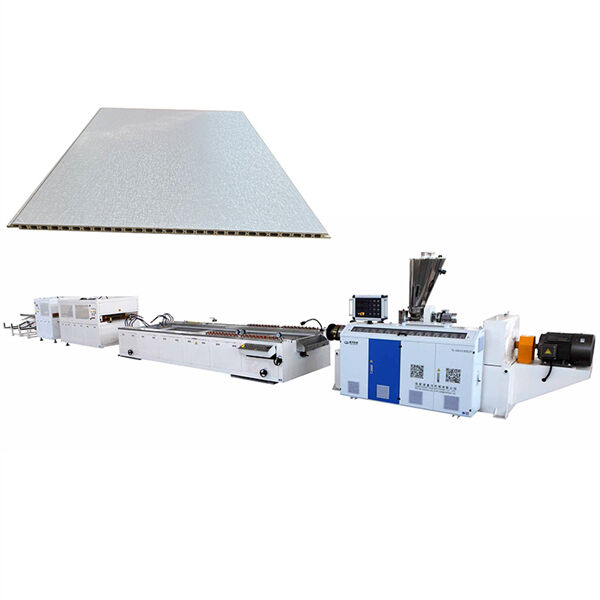

Wall Panel Machine is a huge and powerful machine that can make walls for buildings. Xinhe pvc wall panel making machine can build walls in various sizes and shapes to assist buildings of any design. It can deploy mega tall walls for towering skyscrapers or lower walls suitable for homely abode.

From raw materials such as wood and cement, wall panel is a flat panel produced by the Wall Panel Machine. The panels are assembled to create walls. Xinhe wpc wall panel machine has arms that shift the panels and drop them into place. It has sharp tools as well, which are used to cut the panels with precision and accuracy that is needed for a specific shape panel. A machine carefully stitches everything together ensuring the walls effortlessly fall into place.

This is the core product of the wall panel machine which can be widely acceptable for making walls in building. In the past, when walls were hand built they took a proactive time and required much labor. Everything had to be measured perfectly and each piece had to fit right. But today, Xinhe pvc wall panel machine has made it easier to manufacture the walls. Which is great for builders since they can complete projects quicker and less walls in a small frame of time. Efficiency is good for business as well!

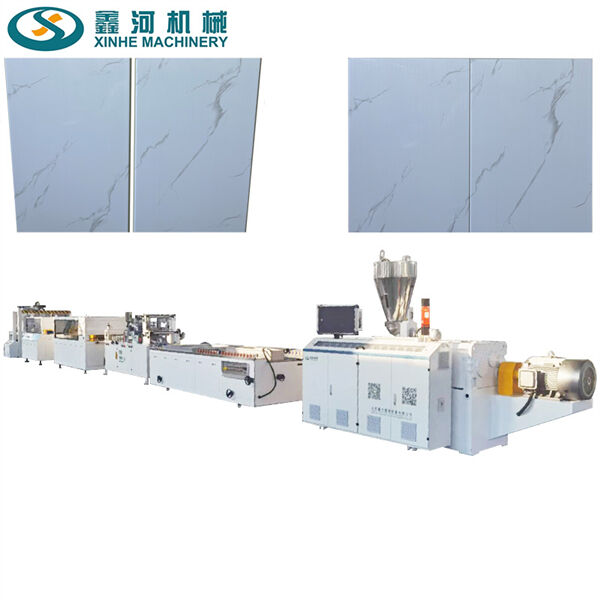

This is also great for wall panel machine building design. It can produce walls in all shapes and sizes-allowing architects to be far more creative. They design more complex or different shaped buildings with the ability to produce their ideas through wall panel making machine. This enables construction in ways that were previously not possible, and as a result more aesthetic form of constructions are now structurally viable.

The wall panel machine allows us to build better, faster and greener. It creates walls which are really strong secure and high quality. It is also eco-friendly, working both at a low energy output and with minimal wastage. This is phenomenal for the environment as it allows us to construct buildings that are resilient and sustainable. The use of the wpc wall panel machine, allows us to create houses that are more friendly with our planet which is equally significant for future generations too.

At Wall panel machine we adhere to the strictest standards regarding the material and thickness of machine steel We also provide a detailed list of dangerous parts Ensuring safety measures our manufacturing lines provide high durability with low failure rates and stable reliable production Our customers rely on their machines for an average of more than 8 years

Pre-Sales: Our sales staff with more than five years of experience, will Wall panel machine the best machine configuration for you. We provide 24 hour service to our clients and offer video tours of the factory.In-Sales: We can provide videos of production, from raw steel to the finished product as well as videos of production on the total line.After-Sales Service: Our engineers offer on-site support for cost and lifelong technical support via video from raw materials to the finished product.

We Wall panel machine the machine configuration to the specific needs of our customers We also provide factory direct sales premium product quality as well as a complete after-sales support Our machines are adored by our customers in Vietnam as well as Indonesia Additionally they enjoy a long lifespan lasting for more than 8 years

We provide custom-made machines that are customized in terms of color, size and even automation. Molds are customizable according to what the final product should look like. As we have grown from Zhangjiagang Wall panel machine Machinery to Jiangsu Xinhe Intelligent Equipment Co., Ltd., we have become one of the top 10 Chinese plastic extrusion line makers.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights Reserved