As a type of wall covering, PVC wall panels are more popular among people for interior decoration of homes, offices and other places now days. Great, these are simple to implement lengthwise up against the wall like paneling and this does succeed quite well for a similar effect. Fortunately, they are available in beautiful colors and constructions to match your decor. But they still take time to make and a lot of work if you're making many panels at once. That is why, several firms depend on special devices to help them produce PVC wall panels in the fastest and also cost-effective way. The Xinhe pvc wall panel making machine is important because they allow a higher number of people to appreciate the aesthetic and practical value incorporated by solar panels in their venues.

The machines used to emboss these panels are highly technical and bring out superior quality wall panel which cannot be achieved with any manual techniques. It guarantees that each panel is exactly the length, width and thickness they should be Such precision is critical here because if errors are made in producing the panels, they might not be properly fitted together during installation. Picture trying to assemble a puzzle with pieces that are all the wrong size; it simply would not fit. The Xinhe pvc wall panel machine also helps to make the panels smoother then even some of them come out with defects that can spoil their appearance. And this great love for detail makes the panels look even better on walls.

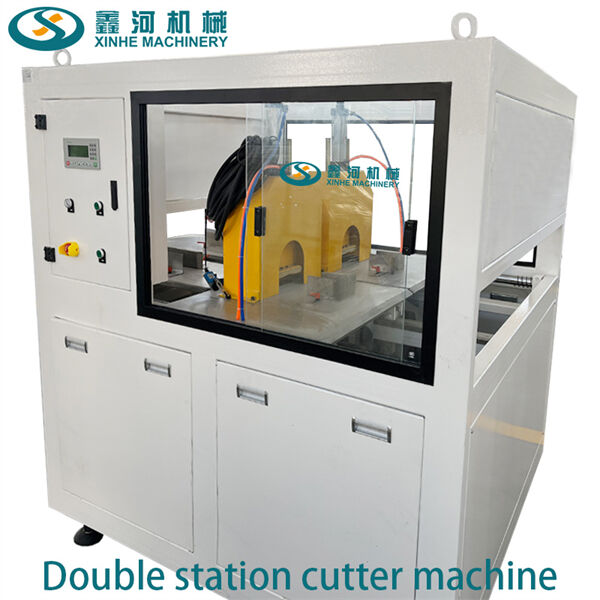

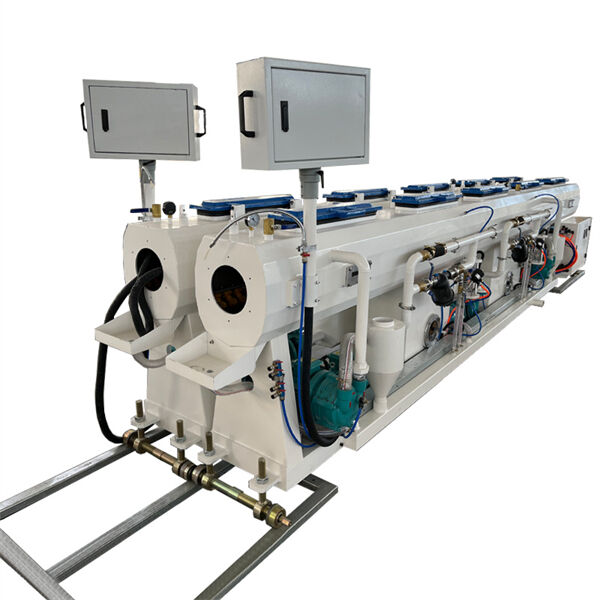

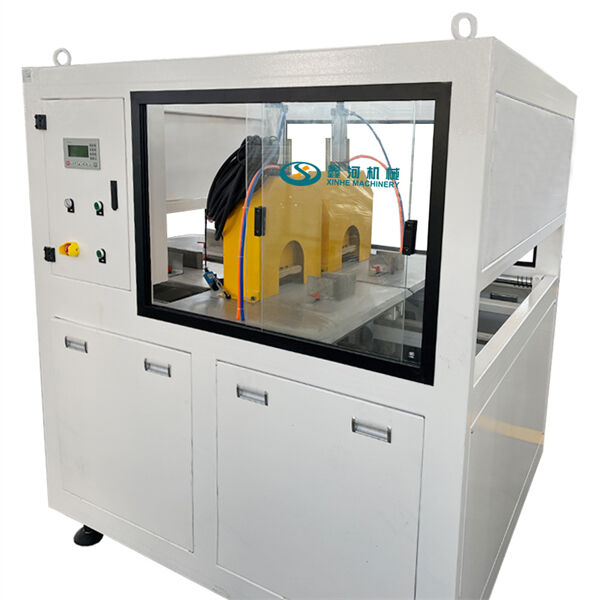

There are some notable features of PVC wall panel machines such as the fact that these they happen to be automated. That means they are able to create a great number of panels in short period. They are very easy to use and even if you have never used one before, you will be a pro in no time. The machine, once fed and with repeater precisely set needs very little involvement from the workers. This not only saves costs in terms of labor, but it also speeds up production, something that is key for companies trying to meet demand.

Another great thing about those machines is that they are environmentally friendly. They consume less power compared to other types of machinery thereby helping in saving energy. Such a great help to our Mother Earth. Machine made panels cause less waste when created as well because such machines make panes very accurately. So that means less PVC is unused, or goes to waste. These machines are becoming increasingly popular in industry because of these eco-friendly features, which help to protect the environment and foster a more sustainable future.

Last but not the least, the PVC wall panels that are produced by these machines is cost-effective as well in addition to being strong and lasting long. Even if it is a more expensive process, the labor costs are cheaper than makers of normal solar panels because this Xinhe pvc wall panel machine can create precise and identical planes with each layer thus using fewer workers effectively lowering cost. They are great for anyone who wants a steal Also, the tiles are going to be capable of lasting for a very long time even when you use them thickly placed which is likely why they will work incredibly well on that hot tub store floor regardless, right? Their durability also makes them an ideal choice for wall decor in any room.

Our machines are arranged to meet the requirements of the client We provide direct sales from the factory premium products and an extensive after-sales service Our machines have a lifespan that exceeds 8 years They are well-received from customers from Vietnam Indonesia Pvc wall panel machine South Africa Bolivia and many other countries

We offer custom Pvc wall panel machine that are customized in terms of size, color as well as automation. We can also design molds based on the finished product. We've evolved from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and have now become one of the top 10 Chinese plastic extrusion lines manufacturers.

At Jiangsu Xinhe we adhere to stringent standards regarding the dimensions and materials of machine steel We also provide the most areas that are at risk The production lines we use are built to be safe with an extended life-span low failure rate and a steady reliable production A Pvc wall panel machine of our clients have had their machines for more then 8 years

Pre-Sales: Our sales team with more than five years of experience, will recommend the most suitable machine configuration for you. We offer customer support 24 hours a day and factory tours with video.In-Sales: Our videos illustrate the manufacturing process starting from raw steel to the finished products.After-Sales: Our engineers offer on-site support for a Pvc wall panel machine and lifetime video technical support starting from raw materials through to the final product.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights Reserved