PVC door profiles are one of the most critical parts for buildings with doors. They help keep the door frames on their hinges and make sure doors can open or close easily. As these profiles are an essential element of every homes and building making pvc door making machine from Xinhe takes huge time as well efforts. For this process, extrusion technology is used to reduce the waste generated in a landfill. The PVC door profile is made faster and of higher quality thanks to this method.

So, what is extrusion? Extrusion process: The extrusion is the process of pushing a material through a shaped opening in a die. Die: This acts like a mould and gives the desired shape to the material, just as we want. Extrusion technology for the production of PVC door profiles employs small pieces of PVC, known as pellets. Melt these pellets and push through the die. This hot profiled PVC use in door manufacturing.

A part of the PVC door profile extrusion machine is a hopper. This is where PVC pellets are delivered to before they are extruded. After the pellets are slid in into hopper, they melt and end up being pressed through die by a screw mechanism. It is the die that ultimately helps create the shape of PVC to get suitable door profiles. One of the top features gone this robot is that it can rule for hours contiguously, making profile after another so opt for upvc door and window making machine from Xinhe.

However, technology has made it be very easy to engage in extrusion processes over the years. Well, machines of these days have the ability to churn out such high quality PVC door profiles at will. The equipment is also equipped with sensors that report if the temperature or pressure of PVC pellets is out-of-limit during melting. This guarantees the correct melting temperature and pressure of the material into a die for producing superior wpc door frame making machine from Xinhe.

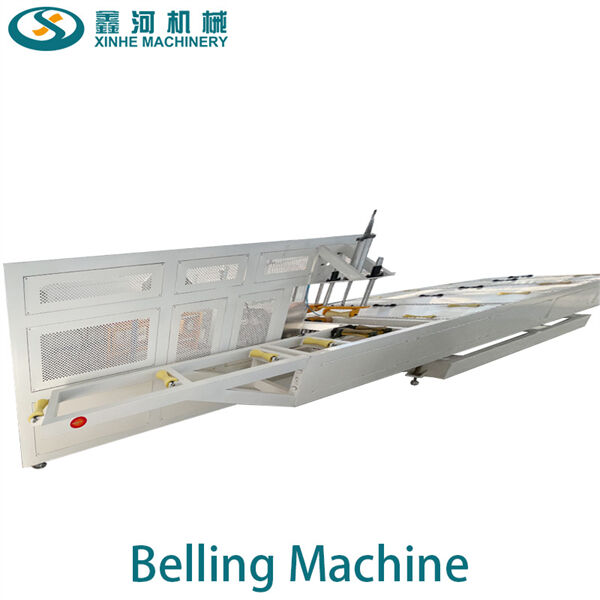

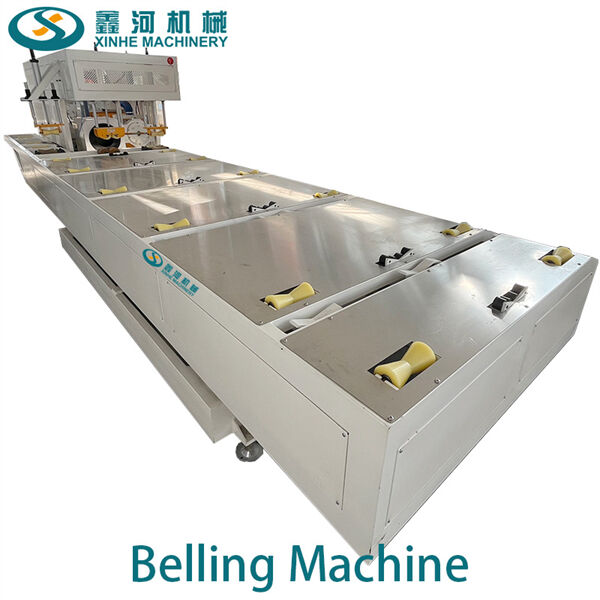

Below you will find images of a PVC door profile extrusion machine which is an invaluable piece of equipment that can do wonders for your business. This upvc door making machine makes it possible to produce PVC door profiles more quickly and with a higher quality than if you used older methods, which means that your overall output can be increased by making products in this way.

It also has the ability to produce various shapes as well as profiles of different sizes. It helps you to target a broader depth of products that can cater the needs of your customer. You can offer your customers the real price of the remedy by making it an affordable option, which cuts out most competition so opt for upvc window and door making machine.

We can tailor the machine configuration according to the particular requirements of our customers Factory direct sales premium product quality and a comprehensive after-sales service Our machines have a lifespan of over Pvc door profile extrusion machine and are highly regarded by clients from Vietnam Indonesia Saudi Arabia South Africa Bolivia and various other regions

At Pvc door profile extrusion machine we adhere to the strictest standards regarding the material and thickness of machine steel We also provide a detailed list of dangerous parts Ensuring safety measures our manufacturing lines provide high durability with low failure rates and stable reliable production Our customers rely on their machines for an average of more than 8 years

Pre-Sales: Our sales staff, with over Pvc door profile extrusion machine of experience, will recommend the best machine configuration for you. We provide 7*24h service to our clients and provide videos of the factory.In-Sales: Our videos demonstrate the manufacturing process starting from raw steel through to finished products.After-Sales Services: Our engineers offer services on-site at cost and lifelong technical support via video starting from raw materials until the completed product.

We offer customized machines in terms of size, color and automation. Molds are customizable in accordance with what the final product is expected to look like. We've evolved from Pvc door profile extrusion machine and have become one of the top 10 Chinese extrusion lines made of plastic.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy