A door making machine can be used by businesses to produce several doors in just a few minutes. Which enables them to construct doors quickly and precisely. Fast, accurate doors mean time and money saved for the companies. Ensuring they can be free to concentrate on other aspects of tools and build a business that thrives in making available the very best doors for their customers.

Just picture making a door without it. This would be pretty difficult to do because all the measurements have to be so precise. The door comes in different dimension ranging from height to width and even the shape of the canopy. If we do not receive the assistance of it, perhaps this door could be broken or lack beauty when hanging in place However, the door making machine ensures that companies get well made doors whose measurements will match respective spaces.

Back in the day, doors were crafted by hand. Electricity had to be hand-measured, cut and then sanded by workers so it was time consuming back-breaking work. This process was also tiresome to do, and more room for error occurred. Thanks to the door making machine, this job is a lot more practical and faster for everyone.

With a door making machine, doors can be built based on what exists in its computer. That means after the measurements and specifications are set up, all you have to do is let the machine with your project. This obviously speeds up the door making process, saves time and guarantees that every single one of those doors is going to be uniform in size and again this is a specie aspect because you want your product or finished part to look all alike.

This enables companies to fabricate doors that keep the rain, snow and sleet away while being strong enough to withstand a great deal of pressure. The technology of the machine it is built in will ensure that all doors are exactly the same, regardless from what type of wood or other materials they are made. Customers that care about quality value this consistency more than you could imagine.

Doors made by a door making machine can be amended and customized to what the customers want/ need, as that is ultimately how companies will make money with their products. This is a suitable machine which can be used to mass produce doors of varying sizes, shapes and styles depending on what people want. This personalization helps brands address the needs and preferences of everyone.

The door making machine will allow companies to build doors for homes, buildings and even cars. Being a versatile machine, it is able to manufacture doors for anything between small houses and large office buildings, as well as work on buses or trucks. This makes it a super useful slogan for many other aspects ensuring flexible scenarios.

Our machines are door making machine to meet the needs of the client We offer factory direct sales top-quality products and an extensive after-sales service Our machines are highly valued by our customers from Vietnam as well as Indonesia Additionally they enjoy an extended life span which is longer than eight years

Pre-Sales: With more than five years of industry experience, our sales team will recommend to you the right door making machine. We offer a 24-hour service to our customers and provide video tours of our factory.In-Sales: Our videos show the production process, from raw steel right through to the final products.After-Sales Service: Our engineers provide an on-site service at a cost and lifetime video technical support from raw materials to finished products.

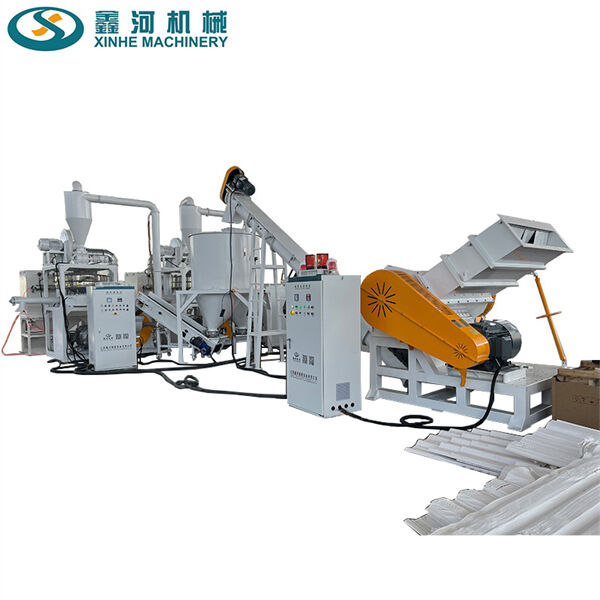

We can door making machine customized machines in terms of color, size and even automation. Molds can be customized depending on the product that is produced. We've grown from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and have become one of the top 10 Chinese plastic extrusion lines manufacturers.

We door making machine strict guidelines for Jiangsu Xinhe for machine steel thickness and material We also offer a list of the most vulnerable components Our production lines are built to guarantee safety and have long-lasting life expectancy and a low failure rate and a steady reliable production A majority of our clients have utilized their machines for more then 8 years

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy