The coolest 3D wall panel you've seen They look really amazing! Believe it or not there is a super machine that can create these amazing wall panels! A 3D PVC wall panel production line. In this post we will learn about all of it from how they work, to those fantastic ceiling panels are made by a machine with lots.

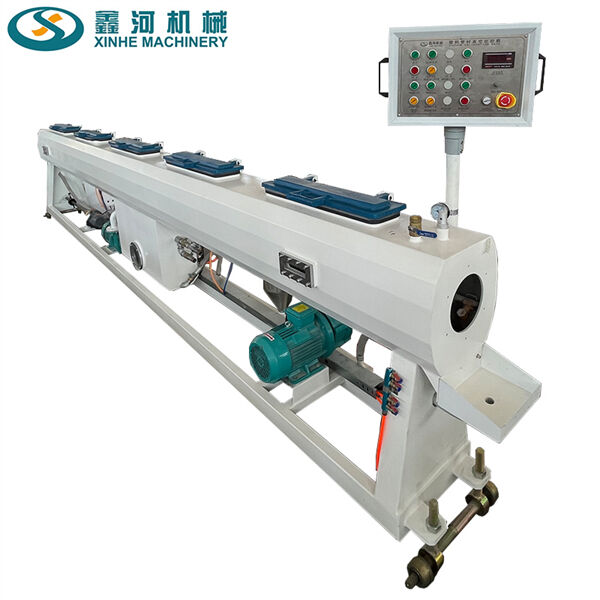

The 3D PVC wall panel making machine is a kind of unique machine, which can make the beautiful 3D wall panels from pvc materials. Many parts make up this machine, and each is very crucial in the process of panel making.

This PVC material is first only fed into the machine. It makes this material malleable by heating it till soften because of the heat. This soft PVC is then forced through a mold by the machine. It establishes a form that gives the PVC shape in the 3D design at hand. Once the PVC has been formed it must be allowed to cool. It dries to a hard solid, producing 3D wall panels that become our beautiful covers for an exciting space.

The 3D printing technique is what makes the special visualization of a 3D wall panel possible. Being far from regular printers that only print flat pictures, this machine is capable to make a tipe of 3D frame design which lay out the wall. This unique process is known as additive manufacturing. This means that the machine simply stacks layers of said soft PVC material on top each other until it has fully created a 3D design. This way, the wall panel has a depth in its details which looks so good.

Here are a few very convincing reason to use 3D PVC wall panel making machine One reason is that it can produce beautiful 3D designs, excellent in wall decoration for houses or offices. The texture and depth of these 3D patterns are completely unmatched by standard wallpaper.

Also, This PVC material has good strength and durability. Which means the 3D wall panels will not break or crack so easily, and that is very important. These panels are also water-proof and fire-resistant. This quality makes them an excellent choice for rooms like kitchens and bathrooms or any place that needs waterproofing (or even fire proofing). The panels are equipped with protection, and you can have them around for years to come.

These 3D tech PVC wall panels are the best option for those of you who may want to bring some style or even texture in a board system for your walls. Customize the (many) 3D designs You can select geometric shapes to draw, or you can take these projects into more detailed and intricate patterns. Thanks to the strength, and durability of PVC material your wall coverings will last through any sort of wear and tear; they are perfect for use in many areas around home or office.

At Jiangsu Xinhe we adhere to the strictest standards regarding the material and thickness of machine steel and provide a detailed list of areas that are at risk Our production lines are built to ensure safety with long lifespan and a low failure rate and a 3d pvc wall panel making machine efficient production Our customers have their machines for an average of more than 8 years

Our machines are configured to meet the demands of the client We offer factory-direct sales high-quality items as well as an extensive after-sales support Our machines have a lifespan that 3d pvc wall panel making machine 8 years They have been well-received by our customers from Vietnam Indonesia Saudi Arabia South Africa Bolivia as well as other regions

We offer customized machines in terms of size, color and automation. Molds are customizable in accordance with what the final product is expected to look like. We've evolved from 3d pvc wall panel making machine and have become one of the top 10 Chinese extrusion lines made of plastic.

Pre-Sales: Our sales staff, with over 5 years of experience, will recommend the appropriate machine configuration for you. We provide 24 hour customer support as well as video factory tours.In-Sales: Our videos demonstrate the manufacturing process starting from 3d pvc wall panel making machine to the finished products.After-Sales Service: Our engineers provide on-site service for a fee and offer lifelong video technical support starting from raw materials to final products.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights Reserved