Do you remember what was written about the machine for PVC extrusion? Its a usefull tool that lets you create several types of plastic objects. In factories where many plastic products are produced, such machines play a crucial role. In this article, you will find a quick guide about these pvinyl chloride extruders - what exactly they are and the things that make them tick.Click here to continue reading>>What is PVC Extrusion Machine?

PVC extrusion machine is one of the specialized machines used to manufacture plastic appliances. In fact, PVC stands for polyvinyl chloride and is a type of plastic active in the English heritage. Pipes for plumbing, window frames of buildings and also colorful toys are made from these PVCs with a use of PVC extrusion machine. The machine itself works in an interesting way, but to keep it simple: the PVC plastic is heated up and extruded through a die. The die is bak You can think of the die like a mold that will form the plastic into its final shape!

A PVC extrusion machine can aid in getting things done faster because you are not doing it all by hand. The machine is able to churn out many products at once and much faster than workers are trying to shape the plastic by hand. This speed allows them to manufacture a large number of items in less time. They can thus save money and also offer competition to other companies that produce the same goods.

So PVC extrusion machines are very important for the production upgrade. Since the machine can probably make as much of these things at once than many people would do with their hands, fewer jobs are needed. Manufacturers will be able to produce more goods in a short period of time because less manual labor is being utilized. This very useful in such cases where there is a hell of demand from customers, and manufacturer can make production indoor this way he cannot miss any claws thrown by the customer-relay team thus always keeping then ahead of their competitors.

A further example of how these machinations assist is reducing wastage. Bend plastic by human hands, there is a lot of excess that has to be thrown out immediately after molding it costs you more expensive and zero gains are made in using up materials. But in the case of a PVC extrusion machine, the plastic is forced through an exacting die. This method is highly waste reducing wrt amount of scrap produced and hence, cost saving for the manufacturers.

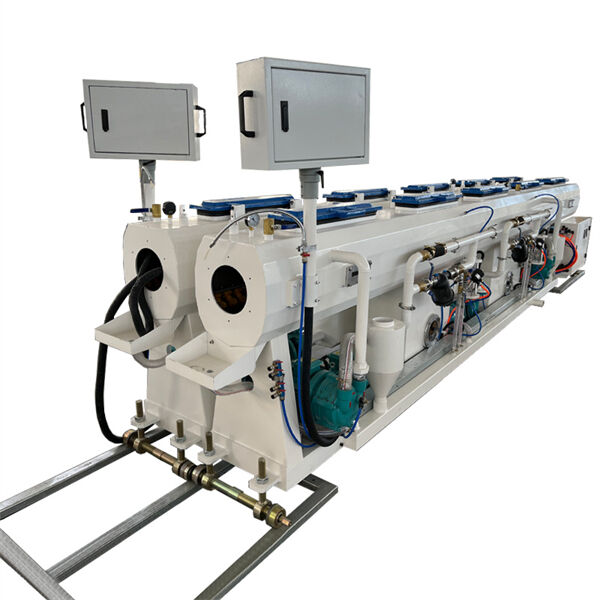

In order to get an idea of how a PVC extrusion machine operates, it is necessary that the different parts are studied in detail. In general, the machine will have a hopper that is basically where you dump plastic pellets. The pellets were then heated to the point where they become molten. Melted plastic is then fed through a long screw that propels the molten liquid. Lastly, the plastic arrives at a die, which forms it to reach that shape.

If you're a manufacturer who wants to purchase PVC extrusion machine, then the first thing that needs your consideration over here is evaluating your business-specific requirements. You must question yourself that - What are the products to abolish? " "How much room do I have to dedicate for a machine and what is my budget for this purchase? "

Pre-Sales: With more than five years of industry experience, our sales team will recommend to you the right pvc extrusion machine. We offer a 24-hour service to our customers and provide video tours of our factory.In-Sales: Our videos show the production process, from raw steel right through to the final products.After-Sales Service: Our engineers provide an on-site service at a cost and lifetime video technical support from raw materials to finished products.

Our machines are arranged to meet the requirements of the client We provide direct sales from the factory premium products and an extensive after-sales service Our machines have a lifespan that exceeds 8 years They are well-received from customers from Vietnam Indonesia pvc extrusion machine South Africa Bolivia and many other countries

We adhere to strict standards in Jiangsu Xinhe for machine steel pvc extrusion machine and the material We also offer a list of vulnerable components We ensure safety by ensuring that our production lines offer long life span and low failure rates and a stable efficient production A majority of our clients have used their machines for more than eight years

We offer customized machines in terms of size, color and automation. Molds are customizable in accordance with what the final product is expected to look like. We've evolved from pvc extrusion machine and have become one of the top 10 Chinese extrusion lines made of plastic.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights Reserved