Apakah kamu pernah bertanya-tanya bagaimana adonan kue, cat, atau obat dicampur dengan begitu menyeluruh? Itu akan sangat menarik untuk membahas dampak keseluruhan dari proses ini! Mixer berkecepatan tinggi, itulah jawabannya! Pertama, mesin-mesin hebat ini dirancang secara khusus untuk memfasilitasi pencampuran bahan dengan cepat dan tanpa ribet. Jadi, orang-orang yang merakit mixer ini menggunakan teknologi canggih, seperti CPU cepat dan algoritma yang baik untuk memastikan semuanya diaduk dengan tepat.

Ada mixer berkecepatan tinggi yang umumnya disebut "mixer putar". Mixer ini memiliki drum bergerak yang menarik di dalamnya, yang bergerak saat proses pencampuran untuk memastikan bahwa segala sesuatu tercampur dengan lancar dan menyeluruh. Tipe kedua adalah mixer statis. Ini menggunakan tabung dan bilah unik untuk mencampur segalanya. Mereka mencampur lebih cepat daripada dua tipe lainnya! Dengan kata lain, Anda bisa membuat kue atau mencampur cat dengan pengaduk ini.

Beberapa perusahaan unggul di atas yang lainnya ketika berbicara tentang mixer kecepatan tinggi, tetapi ada juga beberapa perusahaan lain yang terlibat dalam bisnis ini. Yang terbaik telah membuat banyak mixer, dan selalu memperhatikan pelanggan mereka. Mereka terus berusaha untuk membuat mixer yang sangat kuat dan dapat diandalkan. Anda mungkin pernah mendengar tentang Greaves Cotton Ltd., Eirich, dan Charles Ross & Son Company, ini adalah beberapa produsen mixer teratas. Ketiga merek ini merupakan mixer tugas berat yang bisa menangani banyak pekerjaan dan akan menyelesaikan tugas dengan benar!

MixAnything adalah produk Rob Barre dan setiap kebutuhan bisnis berbeda untuk pencampuran di lokasi. Sebagai contoh, toko roti yang membutuhkan mixer terbaik untuk membuat adonan kue tidak mungkin memerlukan sesuatu yang sekuat dan berbeda dari apa yang diperlukan di pabrik pencampuran industri yang mencampur cat dengan sangat cepat. Inilah sebabnya produsen mixer membuat mixer mereka sendiri untuk memenuhi kebutuhan beragam ini. Ini disebut customisasi!

Ketika membeli mixer berkecepatan tinggi, Anda ingin mesin tersebut tahan lama dan efisien selama mungkin. Inilah alasan mengapa merek mixer terbaik menggunakan bahan berkualitas tinggi untuk membuat mixer mereka. Mereka menggunakan bahan yang kuat dan berkualitas tinggi agar mixer tidak cepat rusak. Selain itu, mereka juga banyak mempertimbangkan konstruksi mixer mereka sehingga dirancang untuk bertahan bertahun-tahun.

Ini adalah contoh substitusi, seperti penggunaan jenis baja unik untuk drum mixer. Ini adalah baja yang sangat keras yang dapat menahan bertahun-tahun aus tanpa menjadi tidak layak pakai. Selain itu, bahan-bahan mereka memiliki baut dan sekrup yang tahan lama dan kuat yang digunakan untuk menjaga semuanya tetap terpasang dengan erat. Semua detail kecil dan pilihan ini bersatu membentuk mixer yang kokoh seperti tank, dan juga cukup baik dibuat untuk jangka panjang!

Fitur Khusus Beberapa hal yang ditawarkan pembuat untuk mencapai keseimbangan ini sudah terdapat dalam desainnya. Mereka juga akan menggunakan komputer untuk mengontrol kecepatan mixer dan berapa lama mixer tersebut mencampur. Jika diperlukan, komputer ini dapat membuat penyesuaian cepat untuk memastikan setiap elemen dalam campuran sempurna...setiap kali. Sebagai alternatif, mereka bisa menggunakan bilah khusus yang diciptakan secara khusus untuk mencampur bahan sebaik mungkin.

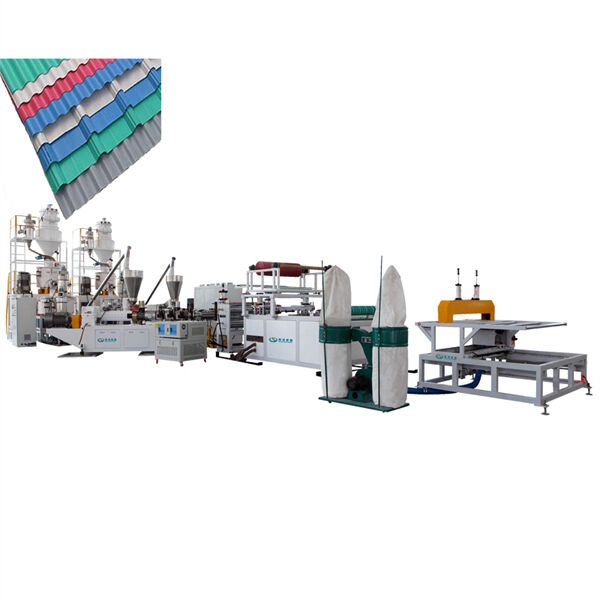

Dengan lebih dari 12 tahun pengalaman dalam ekstrusi plastik, kami menawarkan mesin yang dapat disesuaikan berdasarkan ukuran, warna, dan tingkat otomatisasi. Pabrik pencampur berkecepatan tinggi dapat disesuaikan tergantung pada penampilan produk akhir yang diharapkan. Kami telah berkembang dari Zhangjiagang Xinhe Machinery menjadi Jiangsu Xinhe Intelligent Equipment Co. Ltd. dan sekarang telah menjadi salah satu dari 10 baris ekstrusi plastik teratas di China.

Mesin-mesin kami dikonfigurasi untuk memenuhi kebutuhan klien. Kami menyediakan penjualan langsung dari pabrik, produk dari produsen mixer berkecepatan tinggi, dan dukungan purna jual yang luas. Mesin kami bertahan lebih dari 8 tahun dan diterima dengan baik oleh pelanggan di Vietnam, Indonesia, Arab Saudi, Afrika Selatan, Bolivia, dan banyak negara lainnya.

Sebelum Penjualan: Dengan pengalaman gabungan lima tahun di lapangan, tim penjualan kami akan merekomendasikan konfigurasi mesin terbaik untuk Anda. Kami menawarkan layanan 24 jam kepada klien kami dan memberikan tur video pabrik kami. Selama Penjualan: Kami dapat menyediakan video produksi, mulai dari baja mentah hingga produk jadi serta produsen mixer berkecepatan tinggi untuk seluruh jalur produksi. Layanan Purna Jual: Insinyur kami memberikan dukungan di lokasi dengan biaya nominal dan dukungan teknis video seumur hidup, mulai dari bahan baku hingga produk akhir.

Kami mematuhi standar paling ketat untuk Jiangsu Xinhe terkait ketebalan baja mesin dan material. Kami juga menyediakan stok komponen yang rentan. Pabrikan mixer berkecepatan tinggi yang kami gunakan dirancang untuk menjamin keselamatan, memiliki harapan hidup panjang, serta tingkat kegagalan rendah dan produksi efisien yang stabil. Banyak pelanggan kami telah menggunakan mesin mereka selama lebih dari delapan tahun.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights Reserved