To create these pvc pipes, a place called the pvc pipe production line is needed this is a pvc pipe production line, which means for the large one, there are several machines in a system to produce it. It is essential that this production line is efficient and cheaper than the existing facility. So it should have the capacity to produce a good number of PVC pipes in less money. It saves time and resources for the business, is an environmentally-friendly process.

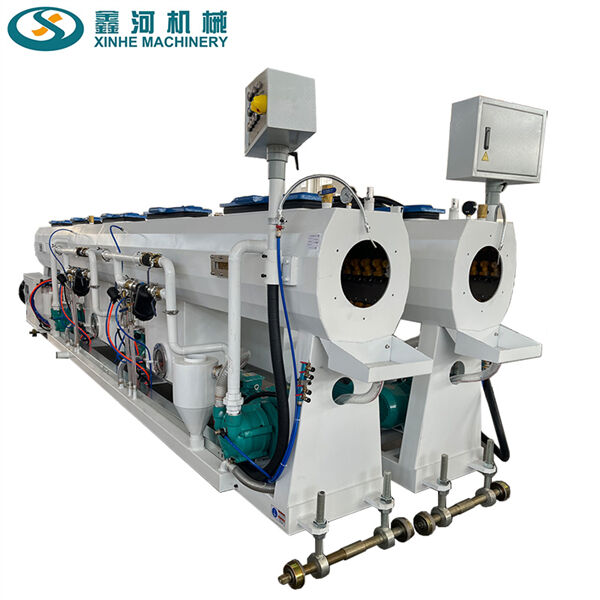

In order to ensure that the PVC pipe production line works very well, we will apply smart technology. This is what makes all the PVC Pipe Extrusion Line from Xinhe are able to work together in a almost synchronized manner ie. as smooth as possible, like any other team could do it while they perform some task thereof. If all machines are talking to each other properly and performing at their best production process is faster.

An extruder is the single most important machine that you will use in your production line. The most important tool of them all, the extruder. During the process, it heats up PVC and then forces it through a mold to create shape in which we want the pipe of PVC.

This is why the PVC pipe production line was formulated. These plastic pipe extruder machine from Xinhe are made up of quality materials like steel, hence these can run for long time without any process disturbance. So, as long as we have a production line that is efficient and robust enough to manufacture significant quantities of PVC pipes around the clock, there will for ever be plenty available for those whom require it.

PVC pipes, do you know that they come in an assortment of sizes? While pipes may be small or large, the size is immaterial. The PVC pipes come in different sizes, according to their use. For instance, small PVC pipes are frequently used to transport water through a home and bigger pipes (such as concrete) must be utilized for moving gas olive significant distances so opt for pvc pipe making machine from Xinhe.

This allows a production line that needs to produce different sizes of PVC pipes, and must therefore be adapted to this need. This allows the fully automatic pvc pipe making machine to make PVC pipes of various sizes. In addition having this flexibility allow us to produce different types of PVC pipes for different kind of applications in accordance with the best needs or requirements that each customer require.

This is why the PVC pipe production line could be environmentally friendly designed as well. The pvc water pipe making machine are so unassuming as to be lost amongst the production line and they consume lesser electricity. This is beneficial for the planet as it cuts down on how much energy we use.

We adhere to the strictest standards for Jiangsu Xinhe for machine steel thickness and materials We also offer an inventory of components that are vulnerable The Pvc pipe production line we use are built to guarantee safety and have a long life expectancy as well as a low rate of failure and stable efficient production Many of our customers have utilized their machines for more than eight years

Our machines are configured to meet the needs of the client We provide factory direct sales Pvc pipe production line products and an extensive after-sales support Our machines last of over 8 years and are well-received by customers in Vietnam Indonesia Saudi Arabia South Africa Bolivia and many other countries

With over 12 years of experience in Pvc pipe production line, we offer machines that can be customized in terms of color, size, and even automation levels. We can also customize molds based on the finished product. We've evolved from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and we are currently one of China's top 10 extrusion lines made of plastic.

Pre-Sales: Our sales staff, with over 5 years of experience, will recommend the appropriate machine configuration for you. We provide 24 hour customer support as well as video factory tours.In-Sales: Our videos demonstrate the manufacturing process starting from Pvc pipe production line to the finished products.After-Sales Service: Our engineers provide on-site service for a fee and offer lifelong video technical support starting from raw materials to final products.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy