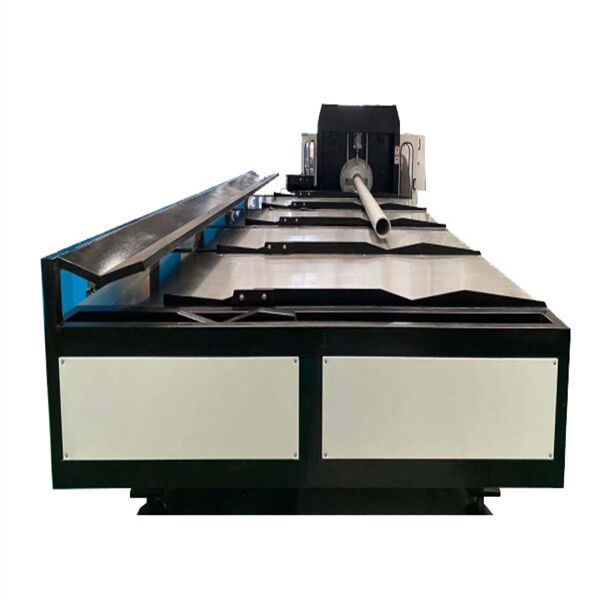

PVC pipe machine, have you ever seen one of these? Xinhe PVC Pipe Belling Machine is a big and impressive machine made to produce PVC pipes. PVC pipes are necessary for a variety of uses, most especially in the movement from one place to another. For example, it would be very difficult to convey drinking water or use it for hygienic purposes without PVC pipes. The amount of water we use each day is just staggering.

PVC pipe machine is manufactured for producing many pipes in a single production process. It functions like the assembly line, which is a unique method of step by step procedure. This means all of the PVC pipes that come out of your machine are identical in size and shape, which can make it much easier when you use them for various projects. Uniform pipes will work well with each other and is very important for things like plumbing in construction.

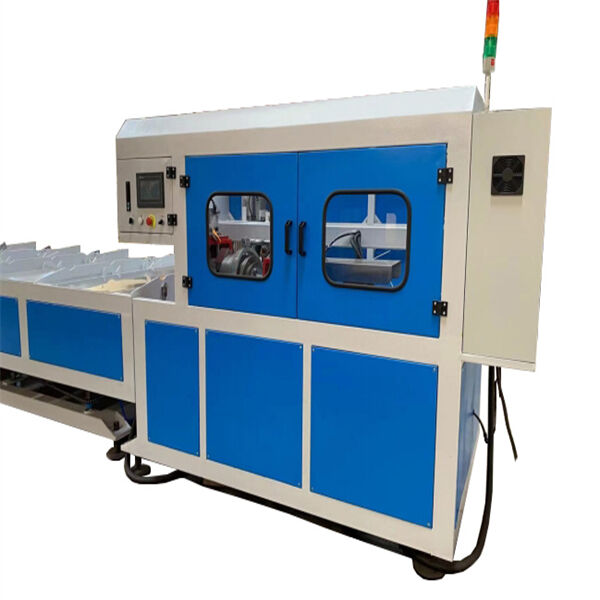

Die- The die is the most important thing that helps in converting PVC to pipes by melting at a certain temperature. The die can be modified or replaced in order to produce pipes with a range of diameters, which is very practical for creating piping that will serve different purposes. It enables manufacturers to design pipes for their own project specific requirements.

The arrival of PVC pipe machine has changed the way how people have been making the material into pipes. Traditionally, PVC pipes were all made by hand which was extremely laborious and time consuming. The amount of time and painstaking accuracy required to create every pipe by hand. And today the Xinhe pvc pipe making machine helps us a lot, we can make many more pipes mechanically and quickly as well.

Also configure the machine to ensure all plumbing pipes are of uniform size and shape. The continuity in supplying ensures that companies get the pipes they require for their projects without having to be bothered with differences in dimensions or strength. This process has increased the overall efficiency with which these conversations can be held.

That is because PVC pipes are durable and last long. They can tolerate lots of pressure, so they are perfect for safe carrying water and other liquids. Moreover, Xinhe fully automatic pvc pipe making machine is an eco-friendly material as it could be again recycled & re-used. This will ensure that rather than ending up in landfill when the pipes have served their useful life, they can be recycled into new items.

So, when you are trying to make PVC pipes then it is very important that the machine for forming this kind of structure must be picked wisely. The ideal PVC pipe machine should function properly, be durable and produce pipes of the same high quality. This will allow you to manufacturer more elbows per pipe using less material, thereby saving time and money down the road.

We customize the configuration of our machines to meet the requirements of our customers factory direct sales premium product quality and a comprehensive after-sales service Our machines last that exceeds 8 years They are highly regarded by clients from Pvc pipe machine Indonesia Saudi Arabia South Africa Bolivia and many other countries

Pre-Sales: Our sales team with more than five years of experience, will recommend the most suitable machine configuration for you. We offer customer support 24 hours a day and factory tours with video.In-Sales: Our videos illustrate the manufacturing process starting from raw steel to the finished products.After-Sales: Our engineers offer on-site support for a Pvc pipe machine and lifetime video technical support starting from raw materials through to the final product.

With 12 years of experience in plastic extrusion, we offer machines that can be customized in terms of Pvc pipe machine, size, and level of automation. Molds are customizable depending on the final product should look like. We have evolved from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and we are currently among China's top 10 extrusion lines for plastic.

We adhere to Pvc pipe machine for Jiangsu Xinhe for machine steel thickness and material We also offer a list of vulnerable components The production lines we use are designed to be safe with an extended life-span low failure rate and a stable efficient production A majority of our clients have been using their machines for more then 8 years

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights Reserved