Extruding machines are one of those special machines which help to make many things we use in our everyday life. These are very beneficial machines as they can manufacture a wide variety of products from Technoshipmil previousblog post tubes, pipes to different shapes that plastic or metal material is made. A crucial kind of extruding machine produces a type of plastic known as PVC. PVC is also pretty neat because it can be as soft, like a rubber duck, or hard alike your toys that you use to play with. There are many areas, where this type of plastic is used like in building and medicine etc., along with toys which give us pleasure.

Extruding machines are essentially giant play dough makers for shaping this material. These machines squeeze a blob of material out through a very small hole the same way we would when using play dough. The tools, called dies can create a large array of shapes from these machines. Its very similar of cookie cutting which we do in our baking. Once the material is cut to the appropriate shape, we can make almost anything!

PVC is a commonly used material for several reasons. It is because it is cheap and convenient to use. PVC extruding machines are rapidlyused to manufacture PVC products. We see PVC everywhere in our daily lives, you just might not know it! It is available in water pipes, electric cables, shower curtains and even medical tubing used in hospitals. PVC pipes are incredibly valuable as it helps bring clean water into our houses and removes dirty water out so we can live in security.

These PVC extruder machines are also superior in nature because they can produce products of different shapes and sizes There one kind of PVC products that is very long and skinny, like the straws we use to drink. Some are wide and solid, like a paper-towel roll. Some are thick stacks of dense plastic tokens - perfect for playing on playground equipment-like structures to our heart's content! Moreover, PVC sheets can be employed in creating Signs & Displays that you might find at locations like stores and parks. PVC is available in a lot of vibrant hues, or as a designer product with nice grooves and gradients. They even look like wood or stone which is pretty cool!

Many parts function together to produce PVC products in a PVC extruding machine. It starts by dumping the material into a big bowl known as a hopper. The material is then fed generally from a hopper to (a barrel containing) the scorching huge screw. This screw is cushioned because it mashes and melts the material making it like a very gooey mass. Then, the thawed PVC is pounded via a die at one end of the device. In a similar way, as you would with your toothpaste tube - when PVC is pushed through the die, it forms to fit that area.

We cannot operate plastic machines without extruding and this is very important equipment that helps produce things faster at less cost. Their work makes it possible for factories to create countless items they use regularly. Another crucial example is perhaps the PVC extruding machines, as it has long been used for plenty of different objects. It is found in numerous industries and helps to protect us, make our lives simpler or bring joy with the products we love. We would not have nearly as many awesome toys, and things to make our lives so much easier if we did not have these PVC extruding machines.

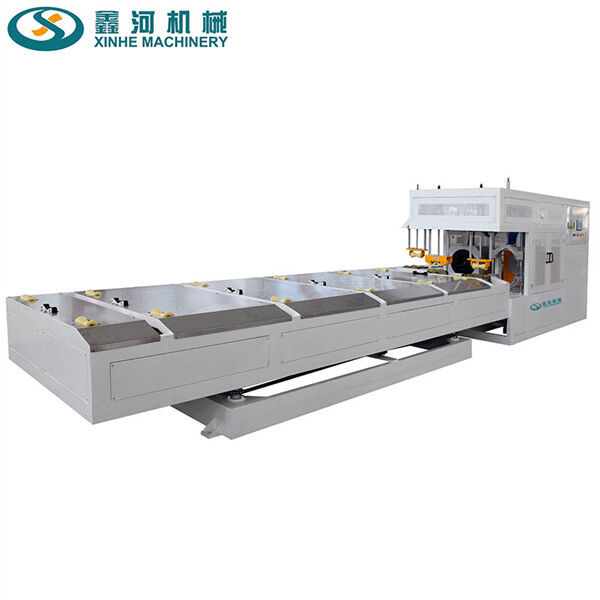

With 12 years of experience in plastic extrusion, we offer machines that can be customized in terms of pvc extruding machine, size, and level of automation. Molds are customizable depending on the final product should look like. We have evolved from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and we are currently among China's top 10 extrusion lines for plastic.

We tailor the machine pvc extruding machine to the specific needs of our customers We also provide factory direct sales high product quality and comprehensive after-sales support Our machines are highly regarded by our clients in Vietnam as well as Indonesia Additionally they have longevity that lasts longer than eight years

We adhere to strict standards in Jiangsu Xinhe for machine steel pvc extruding machine and the material We also offer a list of vulnerable components We ensure safety by ensuring that our production lines offer long life span and low failure rates and a stable efficient production A majority of our clients have used their machines for more than eight years

Pre-Sales: With more than five years of industry experience, our sales team will recommend to you the right pvc extruding machine. We offer a 24-hour service to our customers and provide video tours of our factory.In-Sales: Our videos show the production process, from raw steel right through to the final products.After-Sales Service: Our engineers provide an on-site service at a cost and lifetime video technical support from raw materials to finished products.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy