A PVC sealing machine is required to make the ceilings of this type. This machine is known for its fast and accurate service of offering perfect PVC Panels. This great machine made it possible to produce PVC ceilings at a much faster rate than manual production. It also reduces total construction time, resulting in reduced material and labor costs which makes it ideal for many businesses.

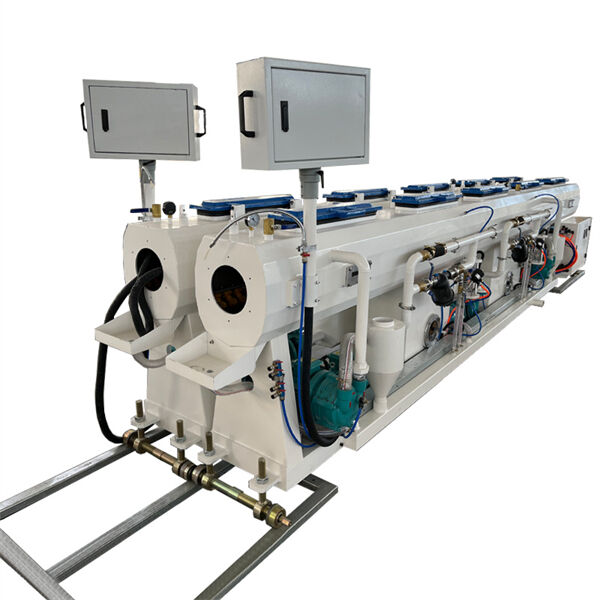

PVC ceiling machines are an innovation in the realm of manufacturing PVC ceilings, also the Xinhe's product such as extruder machine plastic. They use very high technology in these machines to complete more panels as quickly and with less mistakes than manual labour. In this way, manufacturers can develop higher level products even more efficiently. They can also create panels with variable patterns to meet the ever-evolving demand of customers seeking PVC ceilings.

One of the advantages to utilizing PVC ceiling machines is that they are able to be used in large quantities quickly which can often prove difficult with older production methods. Thanks to these types of state-of-the-art protective systems, however, there is a general increasing implementation (and out basis) associated with producers purchasing automated tamper-evident capsuling devices for continual generation. So, this is because lesser manpower will be required and the machines can keep working on their own without receiving high supervision which therefore makes significant increase in production.

You should know that PVC ceiling machines have many different models and types of production, similar to the machines for recycling plastic by Xinhe. Some machines are designed for the production of shiny, glossy PVC ceilings or matte dull finish ceiling. In addition, others of these machines also have capabilities to create various designs and colors which make it very flexible for different types of markets as well various consumer taste.

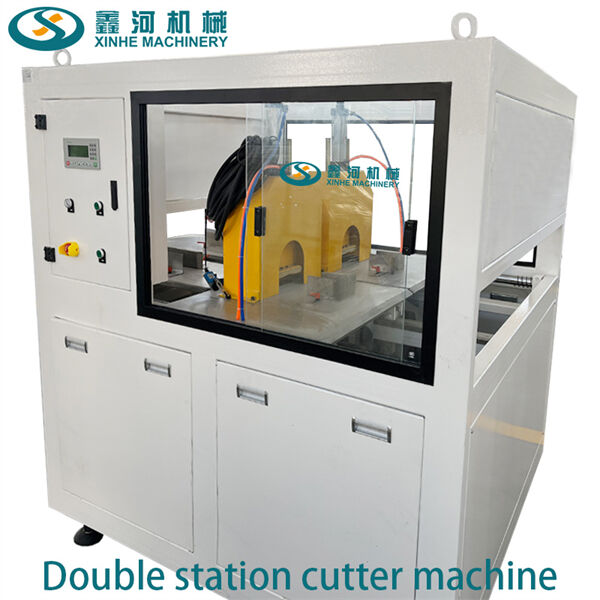

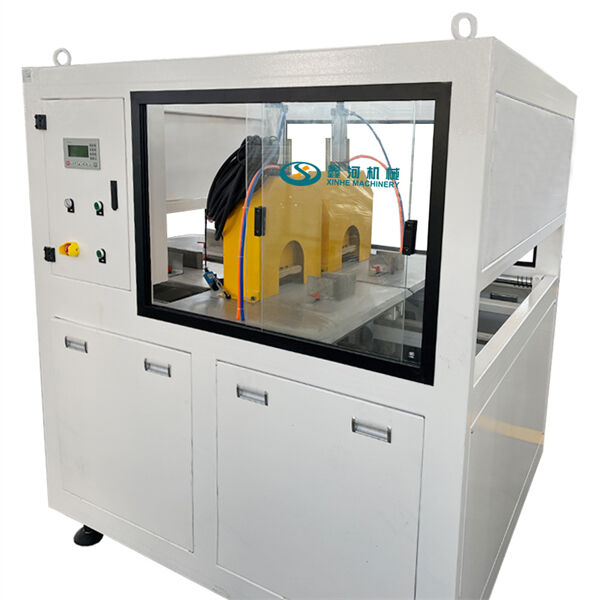

The latest PVC ceiling machines come with state-of-the-art technological features which further enhances the production process, identical to Xinhe's product pe pipe making machine. From getting the row materials to drilling upto PVC ceiling panels. With the most recent machines, some even have an automatic cutting system that reduces waste on any given job so you can by more efficient with your printing assignments. This is a good thing as less material will be wasted and this can save some money and the environment.

PVC ceiling machine manufactures are continually updating the technology of their machines to keep pace and remain relevant, also the plastic pipe extruder machine made by Xinhe. Newer machines utilize computer technology which is referred to CNC (computer numerical control) so that the machine can form beautiful panels with minimum errors. Which means any products these machines make are going to be uniform and adhere to the high standards customers expect.

To sum up, PVC ceiling machines are the best and great technology so that we can change our way of making ceilings, just like the Xinhe's product called plastic extruders. The PVC ceilings ability to knock-out lots of panels by One store and customized on-site are among the main reasons they are rewarding Affordable-unique controlled decorative. These machines also help bring down the cost of production and waste, which makes them a wise economic choice for businesses.

At Jiangsu Xinhe we adhere to stringent standards regarding the dimensions and materials of machine steel We also provide the most areas that are at risk The production lines we use are built to be safe with an extended life-span low failure rate and a steady reliable production A Pvc ceiling machine of our clients have had their machines for more then 8 years

We customize the configuration of our machines to meet the requirements of our customers factory direct sales premium product quality and a comprehensive after-sales service Our machines last that exceeds 8 years They are highly regarded by clients from Pvc ceiling machine Indonesia Saudi Arabia South Africa Bolivia and many other countries

Pre-Sales: With more than five years of industry experience, our sales team will recommend to you the right Pvc ceiling machine. We offer a 24-hour service to our customers and provide video tours of our factory.In-Sales: Our videos show the production process, from raw steel right through to the final products.After-Sales Service: Our engineers provide an on-site service at a cost and lifetime video technical support from raw materials to finished products.

We offer customized machines in terms of size, color and automation. Molds are customizable in accordance with what the final product is expected to look like. We've evolved from Pvc ceiling machine and have become one of the top 10 Chinese extrusion lines made of plastic.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights Reserved