Without any doubt, PE pipes making machine is the only option if you are designing tough and resistant pipes for your construction works. What does PE stand for and why is it used in pipes? This excellent Xinhe pvc pipe making machine takes in raw polyethylene product and contracts it to appropriately extrude long pipes that are flexible like a hose to convey water, gas or any other fluid from one place to another without causing damage.

The PE pipe making machines are perfect for any construction project that requires the use of pipes which should have high quality. The greater quantities of quality products produced at a faster rate is what these machines specialize in as compared to the Xinhe rigid pvc pipe making machine. They will obviously have to operate at a higher speed so more goods can be created daily. Besides, they are also green machines! In comparison with these present day techniques, old ways involved processes which were energy intensive and had a lot of wastages; this means we are going towards having an eco-friendly world.

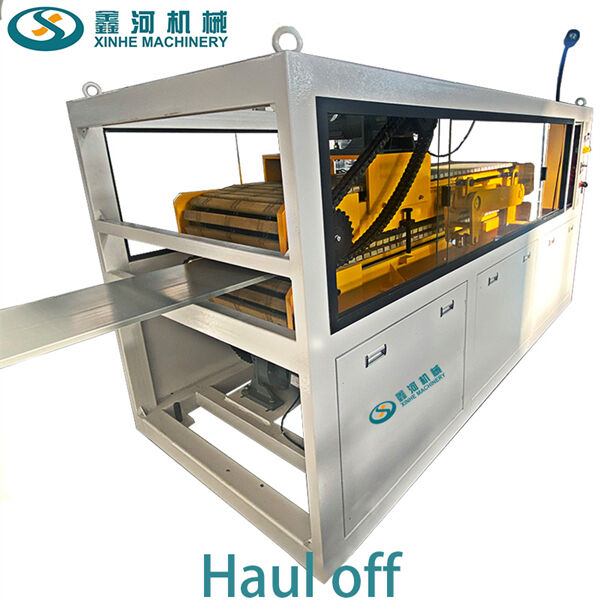

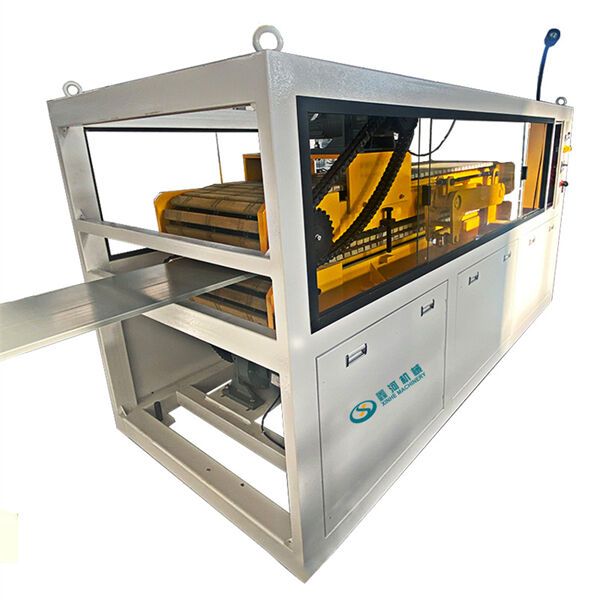

Different tasks on this versatile machine require various moving parts with many pieces. Extruders make up the first part. It melts polyethylene and forms a long tube. A tube shape is formed by forcing molten polyethylene through an extruder. The tube is then cooled in water. At this point, it becomes very essential since cooling makes it possible for the tube to freeze again hence preserving its shape. When the tube has cooled enough, it’s cut into appropriate lengths and then bundled for dispatching.

These machines make tubes efficiently from an environmental point of view as well as economical utilization rates known as ecologies (Meadows et al., 1972). These powers makes tubes in an eco-efficient way. These machines require less energy and fewer resources than older methods do. Pipes that are of high quality, strong enough, but can also be environmentally friendly. Therefore, by using a PE pipe making machine instead, you are actively giving back to our Antalya while still getting the job done right.

For those who want to find the best PE pipe making machine, it will be easier for them to operate this equipment more efficiently and reliably. The machine should have the ability to produce a large number of pipes in minimum time possible. Xinhe pvc garden pipe making machine will help keep things moving fast so your building projects stay on schedule. Equally important is the fact that maintenance and repair of the machine simple. By doing so you will continue operations for many years without major hiccups ironically well in your toes going out of business. For this reason, choosing a wire drawing machine and equipment with right qualities may substantially increase your production as premium quality pipes are stronger and live longer than others do.

We can tailor the machine configuration according to the particular requirements of our customers Factory direct sales premium product quality and a comprehensive after-sales service Our machines have a lifespan of over Pe pipe making machine and are highly regarded by clients from Vietnam Indonesia Saudi Arabia South Africa Bolivia and various other regions

We offer customized machines in terms of size, color and even automation. Molds can be customized according to what the final product is expected to look like. As we have grown from Zhangjiagang Xinhe Machinery to Jiangsu Xinhe Pe pipe making machine Equipment Co., Ltd., we have risen to become one of the top 10 Chinese plastic extrusion line producers.

Pre-Sales: Our sales team with more than five years of experience, will recommend the most suitable machine configuration for you. We offer customer support 24 hours a day and factory tours with video.In-Sales: Our videos illustrate the manufacturing process starting from raw steel to the finished products.After-Sales: Our engineers offer on-site support for a Pe pipe making machine and lifetime video technical support starting from raw materials through to the final product.

At Jiangsu Xinhe we adhere to the strictest standards regarding the material and thickness of machine steel and provide a detailed list of areas that are at risk Our production lines are built to ensure safety with long lifespan and a low failure rate and a Pe pipe making machine efficient production Our customers have their machines for an average of more than 8 years

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy