But do you know what happens to all the plastic that we just toss away? Most of it goes to landfills, which is a fancy word for big fields where garbage hangs out forever - sometimes even hundreds (yas that many) of years later! Because how good can this be for our planet if it tells us that we are using up space for all the garbage we make? There is, however, a way to deal with plastic waste that far outstrips landfill — turn it into something functional! The work of a plastic mill. Plastic mill is a special machine for breaking plastic waste into small pieces, also known as pellets. Remember, these pellets are not just tiny pieces of plastic - they can be made into brand new products! That way we can transform what would be seen as garbage in something of value that cnew be reutilized.

Recycling is so important and it helps us to save the waste as well as our natural resources. The idea behind recycling is to give materials a new life and not rot in the landfills. However, regular cycling also has its downsides as it can be difficult to recycle all types of plastic. This is not always the case, some plastics are unrecyclable and even when they can be recycled into other items, it often turns out to produce lower quality products. So that it can only be recycled a few instances before you need to toss it out. Enter the plastic mill - a game changer! We do this by converting plastic waste to pellets, which means we can also re-use those hard-to-recycle plastics usually destined for landfill. And the best part? The film degrades in only 18 months, allowing the pellets to return to their original state so they are recyclable an infinite number of times without a loss in value. This is much better for our their environment and ensures recycling becomes more effective.

A second round economy is a way to produce objects without Waste. This is about strategy - how do we build and manufacture products that can be used, re-used or deconstructed repeatedly. This is the exact opposite to a linear economy that uses resources, makes things and then dumps it. It is essential in having a circular economy, which this planet desperately needs if we want to keep living on it. When we can reuse and recycle plastic waste rather than sending it to the landfill, it makes a huge difference in helping us move towards a circular economy that doesn't produce so much unnecessary trash. Which means a step closer to getting greener planet, for the animals and plants.

Additionally, the use of a plastic mill is also environmentally and commercially beneficial. It saves businesses money, allowing them to avoid hefty penalties associated with disposing of plastic waste in landfills. Instead of garbage they can convert their waste into useful, valuable stuff with the plastic mill. The pellets produced by the plastic mill can also be returned to businesses for further production, reducing the amount of new plastics required. It is also likely that this will contribute to major savings in cost and reputation as an environmentally friendly company. And for the planet, it helps this reduce some of the plastic waste from landfills or oceans. However, in this way they are helping maintain a very nice and safe environment for the rest of our nature. Not only is this good for the planet, but a cleaner ecosystem also means we live in one too :) And that will be better than anything imaginable for both us and our darlings to come.

We have an issue with plastic in our oceans, harming the animals and even us humans. Millions and millions of tons form every year, winding up in landfills or the ocean where it takes hundreds of years to decompose causing harm on environment. One of the biggest problems is addressed with plastic mills. Through the conversion of these plastic to small pellets, it minimizes the amount of plaatic that are thrown into a pile on land or in oceans. Reduces landfill and reuse things that are difficult to recycle, such as plastics, in turn saves resources and reduce new plastic. Which simply means a better world for us all as we get to live in.

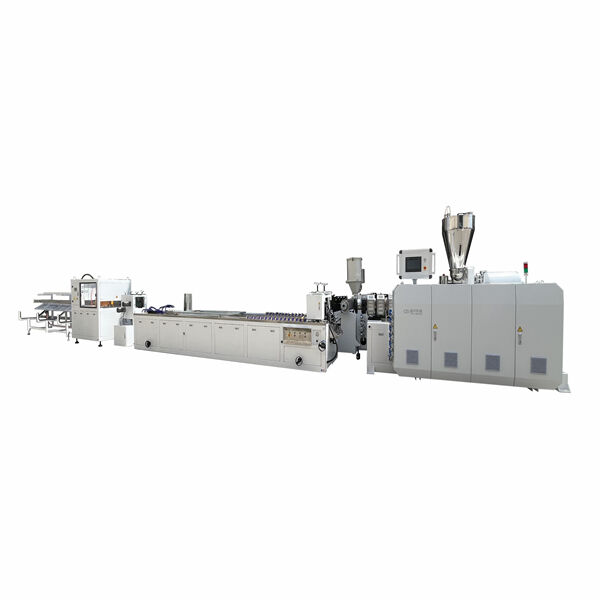

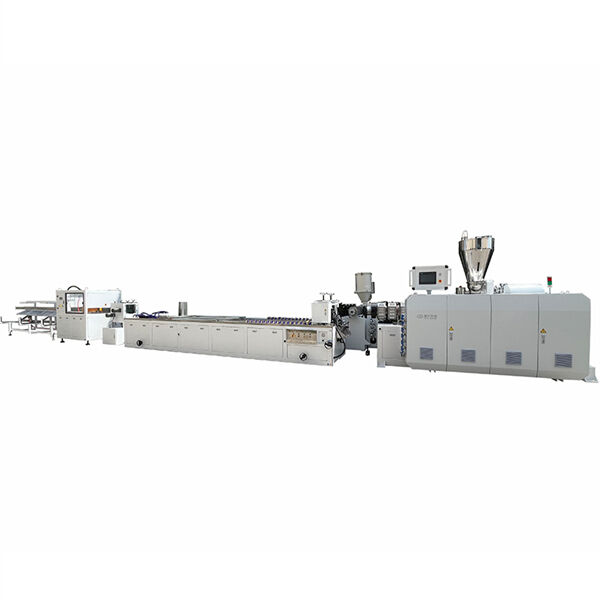

We plastic mill strict guidelines for Jiangsu Xinhe for machine steel thickness and material We also offer a list of the most vulnerable components Our production lines are built to guarantee safety and have long-lasting life expectancy and a low failure rate and a steady reliable production A majority of our clients have utilized their machines for more then 8 years

Our machines are configured to meet the needs of the client We provide factory direct sales plastic mill products and an extensive after-sales support Our machines last of over 8 years and are well-received by customers in Vietnam Indonesia Saudi Arabia South Africa Bolivia and many other countries

We offer custom plastic mill that are customized in terms of size, color as well as automation. We can also design molds based on the finished product. We've evolved from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and have now become one of the top 10 Chinese plastic extrusion lines manufacturers.

Pre-Sales: Our sales team with more than five years of experience, will recommend the most suitable machine configuration for you. We offer customer support 24 hours a day and factory tours with video.In-Sales: Our videos illustrate the manufacturing process starting from raw steel to the finished products.After-Sales: Our engineers offer on-site support for a plastic mill and lifetime video technical support starting from raw materials through to the final product.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy