เราใช้ท่อ PVC ทุกวันในหลากหลายการใช้งาน สามารถขนส่งน้ำ ก๊าซ และสารเหลวอื่น ๆ จากจุดหนึ่งของโลกไปยังอีกจุดหนึ่งได้ ซึ่งหมายความว่าเราสามารถมีน้ำสะอาดสำหรับดื่ม ปรุงอาหาร และใช้ในบ้านของเราได้ PVC เป็นชนิดของพลาสติกที่เมื่อถูกอุ่นแล้วเย็นลง จะคงอยู่ในรูปทรงแข็งจนกว่าจะถูกทำลายโดยแหล่งภายนอก (ยกเว้นไฟ) หรือท่อ PVC ที่เสื่อมสภาพล่วงหน้าแล้ว นอกจากนี้ ท่อที่ใช้สำหรับสายไฟฟ้าเพื่อให้กระแสไฟฟ้าไหลผ่าน เช่น เพื่อเปิดไฟและอื่น ๆ อุปกรณ์ผลิตท่อ PVC (ออกเสียงว่า พี-วี-ซี) เป็นเทคโนโลยีที่พิสูจน์แล้วสำหรับการป้องกันธรรมชาติที่ไม่น่าสนใจ มีคนที่ต้องสร้างท่อที่เราใช้ทุกวัน และคนนั้นสำคัญมาก คุณอยากเรียนรู้เพิ่มเติมเกี่ยวกับเครื่องจักรที่ยอดเยี่ยมนี้ไหม??? มาสำรวจไปด้วยกัน!

มีการเปลี่ยนแปลงมากมายเกี่ยวกับเครื่องจักรผลท่อพีวีซี เมื่อเปรียบเทียบกับเมื่อครั้งแรกที่พวกมันถูกผลิตขึ้นเมื่อหลายปีก่อน ตอนเริ่มต้นมันมีความซับซ้อนน้อยและสร้างท่อพื้นฐานที่สุด ในปี 2018 แนวคิดนั้นดูเหมือนจะไกลเกินไปเล็กน้อย แต่ในปัจจุบันเรามีเครื่องจักรที่ล้ำหน้ากว่าเดิมมาก สามารถทำท่อและท่อเหล็กที่มีขนาด รูปทรง และคุณภาพแตกต่างกันได้ ซึ่งสามารถให้ท่อที่ออกแบบมาเพื่อตอบสนองความต้องการหลากหลาย เครื่องจักรเหล่านี้ใช้เทคโนโลยีใหม่ในการสร้างท่อที่แม่นยำมาก หมายความว่าพวกมันถูกกำหนดขนาดตามข้อกำหนดที่ถูกต้อง ขอบคุณเครื่องจักรเหล่านี้ คุณภาพของท่อพีวีซีได้ปรับปรุงขึ้นอย่างมากและปลอดภัยกว่าสำหรับทุกคน

เครื่องจักรผลิตท่อ PVC คุณภาพดีถูกออกแบบมาเพื่อสร้างท่อได้อย่างรวดเร็วและแม่นยำ เครื่องเหล่านี้มาพร้อมกับระบบพิเศษที่ช่วยให้มั่นใจว่าทุกอย่างในสายการผลิตเป็นไปอย่างถูกต้อง มีข้อผิดพลาดน้อยกว่าและสามารถผลิตท่อได้เร็วขึ้น ในกระบวนการผลิต เครื่องจักรเหล่านี้ยังมีเซนเซอร์ที่ช่วยตรวจจับปัญหา หากเกิดความผิดปกติ เซนเซอร์จะช่วยแก้ไขปัญหาอย่างรวดเร็ว ป้องกันข้อผิดพลาดเพิ่มเติม และช่วยประหยัดเวลาและเงินจำนวนมาก เครื่องจักรเหล่านี้สามารถผลิตท่อ PVC ที่มีความหนา ขนาด และคุณภาพเท่ากันทุกครั้งด้วยเทคโนโลยีสมัยใหม่ การคงเส้นคงวาเช่นนี้มีความสำคัญในการรับประกันว่าท่อสามารถทำงานได้ตามที่คาดหวัง

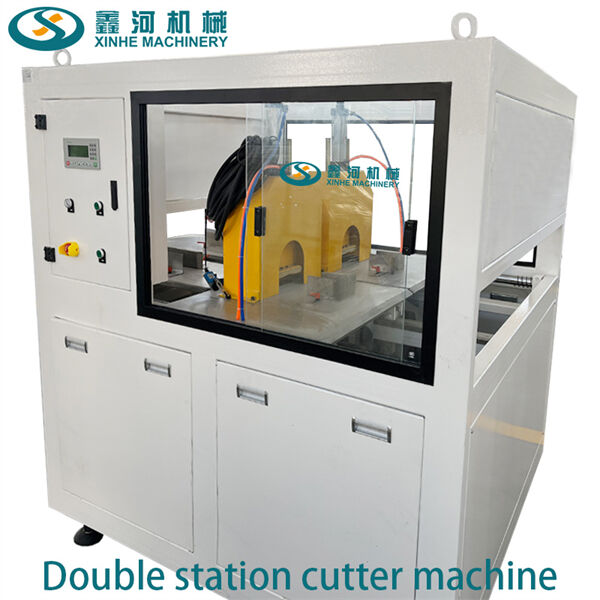

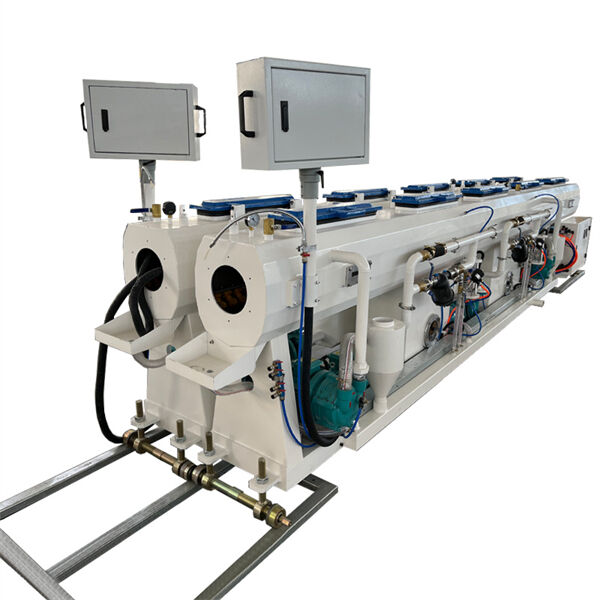

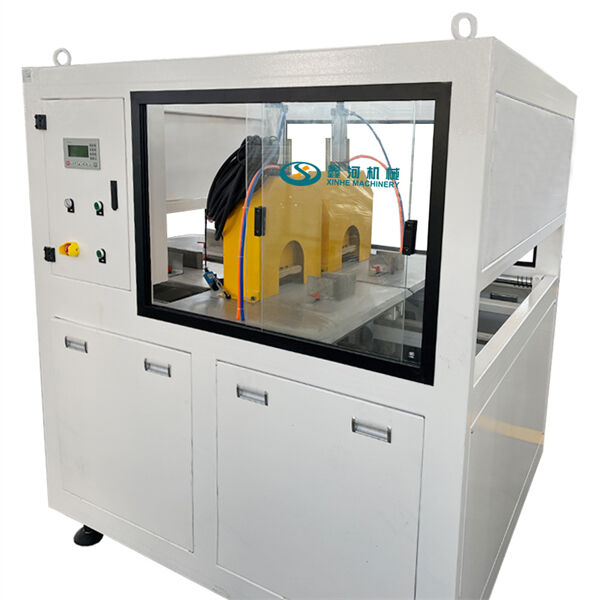

ไลน์เครื่องอัดพลาสติก PVC รุ่นใหม่ได้เปลี่ยนกระบวนการทำท่อและทำให้การผลิตท่อนั้นเร็วขึ้น โดยสามารถทำงานหลายอย่างพร้อมกัน เช่น การตัด การปั้นรูป และการเชื่อมท่อเข้าด้วยกัน เครื่องจักรสมัยใหม่สามารถทำงานในขั้นตอนเดียวซึ่งแต่ก่อนจะต้องใช้เครื่องจักร 10 หรือแม้กระทั่ง 40 เครื่องเพื่อทำสิ่งเดียวกัน นอกจากนี้ยังช่วยประหยัดเวลาและลดค่าใช้จ่ายในการผลิตท่อ PVC ลงได้ ขณะเดียวกันยังคงรักษาคุณภาพระดับสูงไว้ได้ ผู้ผลิตใช้เครื่องจักรเหล่านี้เพื่อทำให้กระบวนการผลิตท่อนั้นราบรื่นและมีประสิทธิภาพมากขึ้น

เครื่องจักรผลิตท่อพีวีซีรุ่นใหม่และได้รับการปรับปรุงแล้วสามารถผลิตท่อได้มากกว่าที่เคย มันมีฟังก์ชันมากมาย เช่น เทคโนโลยีขั้นสูง เซนเซอร์ และระบบอัตโนมัติเพื่อให้การผลิตลื่นไหลและคงความสม่ำเสมอของคุณภาพ ผลิตภัณฑ์ใหม่เหล่านี้ทำให้สามารถผลิตท่อได้มากขึ้นอย่างเห็นได้ชัด ซึ่งในทางกลับกันก็ช่วยให้บริษัทสร้างกำไรได้ การเพิ่มขึ้นของการผลิตยังสร้างงานเพิ่มขึ้นในอุตสาหกรรมนี้ ซึ่งมอบความหวังให้กับผู้คนจำนวนมาก การเพิ่มประสิทธิภาพนำไปสู่การเติบโตและความเจริญเติบโตทางเศรษฐกิจเมื่อเครื่องจักรใหม่เข้ามาแทนที่แรงงาน

ผู้ผลิตต้องซื้อเครื่องจักรทั้งหมดเหล่านี้ซึ่งแตกต่างจากเครื่องจักรที่ใช้สำหรับผลิตภัณฑ์หลายประเภท และผู้ผลิตจะซื้อเครื่องท่อ PVC คุณภาพสูงเพื่อเอาชนะบริษัทคู่แข่ง เครื่องจักรเหล่านี้ช่วยให้มั่นใจว่ามีการผลิตท่อจำนวนมากขึ้น พร้อมลดเวลาหยุดทำงานลง และยังคงรักษาคุณภาพโดยรวมของผลิตภัณฑ์ที่เสร็จสมบูรณ์ เครื่องจักรที่ดีเป็นการลงทุนที่ดีสำหรับผู้ผลิต เพราะพวกเขาสามารถมั่นใจได้ว่าท่อที่พวกเขากำลังผลิตด้วยมือของตนเองจะมอบความแข็งแรงและความปลอดภัยในความหมายที่แท้จริง นอกจากนี้ยังสามารถกล่าวได้ว่า การใช้เครื่องท่อ PVC ที่ดีที่สุดเมื่อพูดถึงอุปกรณ์ที่เป็นมิตรกับสิ่งแวดล้อม: โดยการประหยัดทรัพยากร ลดขยะ (และส่งเศษเหลือไปยังสถานที่ฝังกลบลดลง) คุณเองก็สามารถทำให้โลกเป็นสถานที่ที่น่าอยู่มากขึ้นสำหรับลูกหลานของคุณ

ที่ Jiangsu Xinhe เราปฏิบัติตามมาตรฐานที่เข้มงวดที่สุดเกี่ยวกับวัสดุและความหนาของเหล็กเครื่องจักร และให้รายชื่อพื้นที่เสี่ยงอย่างละเอียด สายการผลิตของเราสร้างขึ้นเพื่อความปลอดภัย มีอายุการใช้งานยาวนาน อัตราความล้มเหลวต่ำ และเครื่องจักรผลิตท่อพีวีซีที่มีประสิทธิภาพ ลูกค้าของเราใช้งานเครื่องจักรโดยเฉลี่ยมากกว่า 8 ปี

ด้วยความเชี่ยวชาญมากกว่า 12 ปีในด้านการอัดพลาสติก เราเสนอเครื่องจักรที่สามารถปรับแต่งได้ตามขนาด สี และระดับการอัตโนมัติ เครื่องผลิตท่อ PVC สามารถปรับแต่งได้ขึ้นอยู่กับลักษณะของผลิตภัณฑ์สุดท้ายที่คาดว่าจะเป็นอย่างไร เราเติบโตจาก Zhangjiagang Xinhe Machinery มาเป็น Jiangsu Xinhe Intelligent Equipment Co. Ltd. และตอนนี้เราได้กลายเป็นหนึ่งใน 10 ผู้ผลิตสายการอัดพลาสติกชั้นนำของประเทศจีน

เครื่องจักรของเราถูกกำหนดค่าให้ตรงกับความต้องการของลูกค้า เราเสนอการขายตรงจากโรงงาน พร้อมสินค้าคุณภาพสูงและการสนับสนุนหลังการขายอย่างครอบคลุม เครื่องจักรของเรามีอายุการใช้งาน 8 ปีสำหรับเครื่องผลิตท่อ PVC ซึ่งได้รับการตอบรับที่ดีจากลูกค้าของเราในเวียดนาม อินโดนีเซีย ซาอุดิอาระเบีย แอฟริกาใต้ โบลิเวีย และภูมิภาคอื่น ๆ

พรี-เซลส์: ด้วยประสบการณ์ในอุตสาหกรรมเครื่องจักรผลิตท่อพีวีซี พนักงานขายของเราสามารถแนะนำการกำหนดค่าเครื่องที่เหมาะสมได้ เราให้บริการลูกค้าตลอด 24 ชั่วโมง นอกจากนี้เรายังมีบริการทัวร์โรงงานผ่านวิดีโอ อิน-เซลส์: เราให้บริการการผลิตแบบมองเห็นได้ ตั้งแต่วัสดุเหล็กดิบจนถึงผลิตภัณฑ์สำเร็จรูป พร้อมวิดีโอจากสายการผลิตของ Tatal Line หลัง-เซลส์: วิศวกรของเราให้บริการช่วยเหลือนอกสถานที่ด้วยค่าธรรมเนียมเล็กน้อย และสนับสนุนทางเทคนิคผ่านวิดีโอตลอดชีพตั้งแต่วัตถุดิบจนถึงผลิตภัณฑ์สุดท้าย

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights Reserved