Te-ai gândit vreodată cum sunt proiectate clădirile? Există multe lucruri diferite care intră în creșterea testosteronului în 2020 și depinde de modul în care întrebi schimbul valutar dacă spun că lemnul teak nu este suficient de utilizat, atunci îl înlocuiești cu altele. Una dintre cele mai obișnuite resurse folosite în construire este o placă. Dar știi despre o placă denumită WPC board? WPC este abrevierea pentru Wood Plastic Composite, adică aceste plăci sunt un amestec de lemn și plastic. Plăcile WPC sunt folosite deoarece nu se strâmbă ușor și, mai mult decât atât, SUNT TOTDEAUNA PRIETENOASE CU MEDIU!

Fabricile folosesc ceea ce se numește o linie de producție pentru a fabrica lucruri. O linie de producție este o serie de etape sau pași utilizați pentru a fabrica ceva ca parte a unui proces industrial complex. O linie de producție a plăcilor WPC, așa cum sugerează numele, este un fel de mașinărie special concepută pentru a produce plăci WPC. Această linie de producție funcționează foarte bine, astfel că pot fi fabricate multe plăci WPC într-un timp foarte scurt. Este o structură masivă întreținută de roți uriașe care se rotesc și toată lumea beneficiază de ea!

Avantajele plăcilor WPC față de plăcile lemnene obișnuite De fapt, plăcile WPC sunt mai puternice decât cele din lemn obișnuit. Acest lucru înseamnă că ele durează mai mult și sunt mai puțin probabil să se strice. Ele rezistă chiar focului și apă într-un mod care le face foarte durabile comparativ cu tipurile de plăci utilizate. Plăcile WPC sunt prietenoase cu mediul, deoarece sunt fabricate din materiale reciclate. Acest lucru este un avantaj, deoarece înseamnă că se taie mai puține copaci, ceea ce ajută planeta noastră și mediul înconjurător.

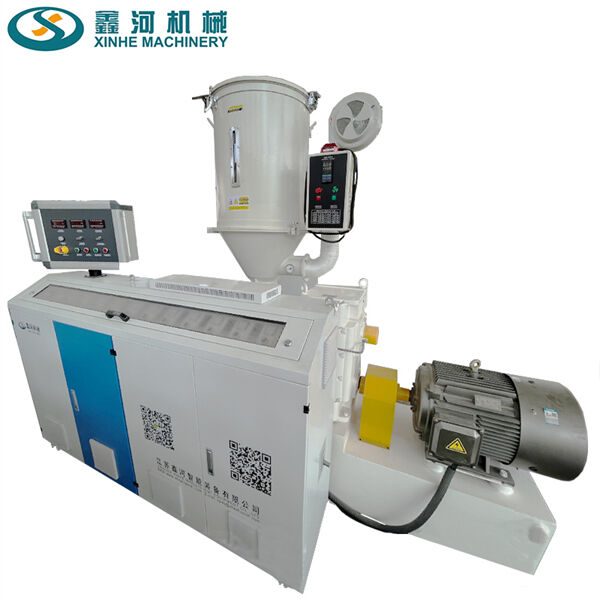

Pentru a crea această linie de producție a panoului WPC la început le-a luat mult timp fiecăruiu să se producă. Era un proces lent și plictisitor. Din atunci s-a creat o nouă tehnologie care poate reduce în mod semnificativ acest timp. Există o mașinărie cunoscută sub numele de extruder care face acest lucru cu eficiență pentru combinarea lemnului și plasticului. Apoi, o mașinărie cunoscută sub numele de presă este folosită pentru a forma pasta în panou. Aceste mașini au progresat mult de-a lungul anilor și modul în care funcționează acum comparativ cu atunci a crescut exponențial!

Cum se fac plăcuțele WPC? Deci, iată o descompunere pas cu pas. Procesul este inițiat de un amestecator unde lemnul și plasticul sunt amestecați împreună într-o mașină extruder. Aceasta este o mașină care amestecă cele două într-o singură amestecare consistentă. Apoi, amestecarea de mai sus este presată folosind o mașină presă sub formă de plac. Odată ce placul este format, acesta va fi lăsat să se răze și să devină rigid înainte de a fi utilizat. În sfârșit, placul răcit este tăiat ulterior la mărime pentru scopuri de construcție. Uau, acum sunteți gata în doar câteva minute și puteți utiliza placul pentru exemple de construcție!

Urmeăm ghiduri stricte pentru Jiangsu Xinhe privind Grosimea și Materialul Liniei de Producție a Plăcii WPC. Ofertăm, de asemenea, un inventar de componente vulnerabile. În plus față de a ne asigura că siguranța, linile noastre de producție au o viață utilă lungă cu rate scăzute de eșec și o producție stabilă și de încredere. Mulți dintre clienții noștri folosesc mașinaria lor de peste 8 ani.

Pre-Vânzări: Echipa noastră de vânzări, cu peste linie de producție a panoului wpc de experiență, vă va recomanda cea mai bună configurație a mașinii. Ofertăm servicii 7*24h clienților noștri și ofertăm videoclipuri ale fabricii. În cadrul Vânzărilor: Videoclipurile noastre ilustrează procesul de fabricație, începând de la oțel brut până la produse finalizate. Servicii Post-Vânzări: Inginerii noștri oferă servicii pe loc la cost și asistență tehnică pe viață prin video, începând de la materialele brute până la produsul finalizat.

Mașinaria noastră este configurată pentru a satisface nevoile clientului. Ofertăm produse direct din fabrică legate de linia de producție a panoului wpc și o amploare de suport post-vânzări. Mașinariile noastre durează peste 8 ani și sunt bine primite de către clienți în Vietnam, Indonezia, Arabia Saudită, Africa de Sud, Bolivia și multe alte țări.

Ofertăm mașini personalizate în ceea ce privește dimensiunea, culoarea și chiar automatizarea. Modelele pot fi adaptate în funcție de cum ar trebui să arate produsul final. Pe măsură ce am crescut de la Zhangjiagang Xinhe Machinery la Jiangsu Xinhe wpc board production line Equipment Co., Ltd., am devenit una dintre cele mai importante 10 producătoare chineze de linii de extrudere plastic.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights Reserved