Hallo, vrienden! Of hebben jullie al overwogen om WPC boards machines te gebruiken?? Dit is geweldig omdat het ervoor zorgt dat de hout-en-plastic panelen lang meegaan. WPC staat kort voor Wood-Plastic Composite, soms hebben we allemaal de mix van hout met loodzaam gezien. In deze post gaan we bespreken hoe deze machines werken en waarom ze belangrijk zijn!

Terwijl bij WPC-dekens de houtdeeltjes worden gemengd met plastic en andere chemicaliën. Deze combinatie biedt een bestand, stijf dek met talloze toepassingen. Dit wordt vervaardigd in de vorm van deze handgemaakte panelen en combinaties die worden gedaan met enkele zelfgemaakte elementen die samen worden georkestreerd, gedroogd, zodat ze eruitzien als vaag afkomstige beelden uit schaduwen, waardoor deze geweldige abstracte concepten bruikbare vormen krijgen. Dit is een lang proces en om eerlijk te zijn is het zwaar werk om dit handmatig te doen. Maar deze staat van kunst apparaat kan binnen seconden hetzelfde werk doen!

Goede WPC bordmachines bieden een bedrijf zoveel voordelen. Ze maken sneller meer panelen. Het is winstgevend: het bedrijf kan meer panelen verkopen en eruit halen een winst daarvan. Hogere winsten voor het bedrijf (hogere omzet). De introductie van nieuwe machines kan ook in zekere mate betere kwaliteit en duurzamere panelen opleveren. Klanten komen terug als je hoogwaardige producten levert.

Met de hedendaagse WPC-plaatmachines kan een bedrijf zijn werk veel gemakkelijker uitvoeren. Omdat werknemers minder fysiek hoeven in te zetten en veel stappen in de productie worden geautomatiseerd met deze machines. Dat bespaart niet alleen tijd en geld, maar het laat mij ook meer voorraad klaarleggen voor verwerking in plaats van waardevolle uren te verspillen aan kalibreren/instellen van de machine. Dit resulteert in een efficiëntere operatie en laat werknemers andere cruciale activiteiten overzien.

ebarrell: Dit was inderdaad een grote verrassing en creëert duidelijk een totaal nieuw beeld voor elk bedrijf met snelle WPC-vloerbedekking machines. Deze machines zijn ontworpen om snel te leveren en dat doen ze ook. Dit is bedoeld om ervoor te zorgen dat bedrijven hun productiedoelen halen en de eisen van hun klanten vervullen. Deze snellere productie betekent ook dat een bedrijf orders sneller kan afhandelen, en tegelijkertijd blijft bijbenen in het snel versturen van deze items. Bovendien kunnen deze machines helpen om de hoge kwaliteit en sterkte van de panelen te waarborgen, zodat ze niet gemakkelijk breken tijdens gebruik. Dit zal invloed hebben op klanttevredenheid.

Dit helpt bedrijven om competitiever te zijn met de meest recente WPC-board machine-oplossingen die beschikbaar zijn. Met de nieuwste technologieën kunnen bedrijven hun interne aanbod bijwerken en concurrerendere producten aan klanten aanbieden. Machines die minder waarschijnlijk zijn om stuk te gaan, zijn machines met een goede relatie tussen betrouwbaarheid en onderhoud. Het betekent eenvoudigweg dat bedrijven hun tijd kunnen doorbrengen met wat ze goed doen, in plaats van de hele dag dingen te repareren. Producten Maken & Verkopen! Uiteindelijk is dit goedkoper en dus winstgevender voor het bedrijf.

We passen de configuratie van onze machines aan om aan de eisen van onze klanten te voldoen, fabrieksrechtse verkoop, premiumproductkwaliteit en een uitgebreid nasverkoopsservice. Onze machines hebben een levensduur die meer dan 8 jaar overschrijdt. Ze worden zeer gewaardeerd door klanten uit Indonesië, Saoedi-Arabië, Zuid-Afrika, Bolivia en vele andere landen.

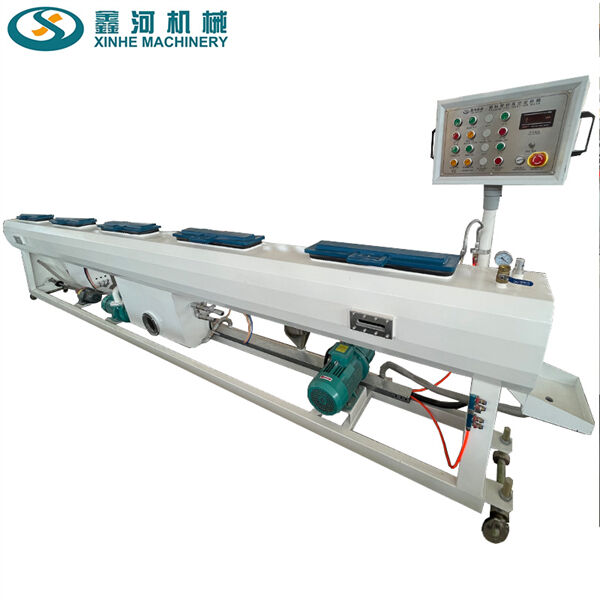

We bieden machines voor de productie van wpc-platen aan die kunnen worden aangepast in terms van formaat, kleur en automatisering. We kunnen ook vormgevingen aanpassen volgens het eindproduct. Van Zhangjiagang Xinhe Machinery tot Jiangsu Xinhe Intelligent Equipment Co., Ltd., zijn we gegroeid tot een van de top 10 Chinese producenten van extrusielijnen voor kunststof.

wpc board manufacturing machine: Met meer dan vijf jaar ervaring in de branche kan ons verkoopsteam de juiste machineconfiguratie aanraden. We bieden 24 uur per dag service aan onze klanten. We bieden ook videobeelden van onze fabriek aan. Verkoop: Onze video's laten het productieproces zien vanaf rauwe staal tot afgeronde producten. Nasaleveringsdiensten: Onze ingenieurs bieden betaalde terplekke diensten en levenslange technische ondersteuning via video, van rauwe materialen tot het eindproduct.

Bij Jiangsu Xinhe houden we ons aan de strengste normen met betrekking tot het materiaal en de dikte van machine staal en bieden we een gedetailleerde lijst van gebieden die in gevaar verkeren. Onze productielijnen zijn gebouwd om veiligheid te waarborgen, met een lange levensduur, een lage defectiefrequentie en efficiënte productie van wpc-bordmachines. Onze klanten gebruiken hun machines gemiddeld meer dan 8 jaar.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights Reserved