Kas ir plastmasas pulverizēšanas mašīna? Tas ir brīnišķīgs aparāts, kas atjauno plastmasas atkritumus, pārvēršot tos par mazām daļiņām. Šīs plastmasas daļiņas var tikt atkārtoti izmantotas dažādos veidos! - Tas ir svarīgi, jo tas palīdz uzturēt mūsu planētu tīru, samazinot plasts, kas beidzas uz bagāžu vietas vai piesārņo okeānus laikā.

Mašīnas uz pulvera plastmasas darbojas ļoti strauji, kas ir viens no to labumiem. Tas ir princips: tās var apstrādāt lielas daudzumus plastmasas atkritumu uz nelielu laiku. Šis tempers ir ideāls uzņēmumiem, kuri vēlas palielināt savu ilgtspēju un pozitīvi ietekmēt situāciju citādi. Turklāt plastmasas pulverizēšanas mašīnas izmantošana var uzņēmumiem nodrošināt naudas taupīšanu, jo atkritumi, kuri citādi būtu nonākuši uz likvidēšanu vai reciklēšanu, tiek saglabāti un atkārtoti izmantoti, neievērojot jaunu materiālu iegādi. Tas ne tikai nodrošina uzņēmuma naudas taupīšanu, bet galu galā nozīmē arī planētas aizsardzību.

Plastmasas atkritumi tiek pārstrādāti, izmantojot augstklasēju mīņošanas tehnoloģiju, kas nodrošina precizitāti. Kā tas darbojas: Pastāv noteikta tehnoloģija, kas ļauj plastmasas pulverizatoriem sadalīt lielos un lapainos plastmasas atkritumus uz mazām, vienmērīgām daļiņām. Ar precīzu mīņošanu plastmasas daļiņas var iznākt pilnībā identiskas attiecībā uz izmēriem. Tas, kas padara to nozīmīgu, ir tas, ka dažiem produktiem ir nepieciešams noteikts izmērs, lai tiktos pareizi izgatavoti. Piemēram, ko darīt, ja jums jāizgatavo plastmasas komponenti automobilim - šīs daļiņas jābūt noteiktā izmērā un formā, kas pieskaitās viena otrai.

Plastmasas pulverizators ātri mīnā, lai iegūtu detaļu medicīnas atkritumu plastmasu. - Pirmo reizi apstrādāts ar diska veida polietilēna pulverizatoru. Šis process notiek ļoti ātri un to var paveikt dažās sekundēs. Plastmasas pulverizācijai jāspēj sasniegt flāšu kā ātri kā gabaliņi, kas ir obligāta saite āru mīņotāju iemeslu dēļ. Daudzi produkti uzskata, ka šī konsekvensa sniegšana ir būtiska.

Mašīna krājot plastmasu ļauj atkārtoti izmantot neizmantoto plastiķu. Tādējādi jums nav vajadzības pirkt jaunus materiālus produktu izgatavošanai. Jūs varat arī ietaupīt naudu, vienlaikus aizsargājot vidi, izmantojot plasta atkritumus. Tas ir uzvaras situācija gan uzņēmumiem, gan vides labā!

Kopš plasts, sadalīts mazos daudzinos, kā lietus putra vienmērīgi izklājas, sulauku platums bērnu audzēšanai bez - dziļuma: 0mm zemes līmeņa izlīdzinātāji, kas nav viegli saņem fine sulauks šo vietu. Ir mašīnas, kas dizinētas konkrētiem plasta atkritumu veidiem, un arī tādas, kas var apstrādāt dažādus veidus. Šī elastība ir svarīga, jo uzņēmumiem bieži vien ir jāstrādā ar dažādiem plasta veidiem.

Turklāt, dažās biznesa nozarēs var būt nepieciešams vairāk atkritumu plastmasas pārstrāde. Tāpēc daudzas plastmasas pulverizēšanas mašīnas viegli var tikt pielāgotas, lai atbilstu dažādām lietojumprogrammām un specifikācijām. Piemēram, ja jums ir nepieciešama īpaša krāsa vai pat plastmasas gabalu izmērs, tad var tikt izveidota piemērota mašīna, kas atbilst jūsu prasībām. Šis pielāgotais process nodrošina, ka uzņēmums vienmēr saņem to, kas tam ir nepieciešams, lai veiksmīgi attīstītos!

Pirms pārdošanas: Mūsu pārdošanas komanda ar vairāk nekā pieciem gadu pieredzi iesaka vispiemērotāko mašīnas konfigurāciju jums. Mēs piedāvājam klientu atbalstu 24 stundas dienā un fabrikas ekskursijas ar video. Pārdošanas laikā: Mūsu video ilustrē ražošanas procesu, sākot no neapstrādātā dzelzs līdz beigtermes produkta. Pēc pārdošanas: Mūsu inženieri piedāvā vietējo atbalstu plāstmašīnu pulverizatoram un garlaicīgu video tehnisko atbalstu, sākot no neapstrādātajiem materiāliem līdz beigtermes produktam.

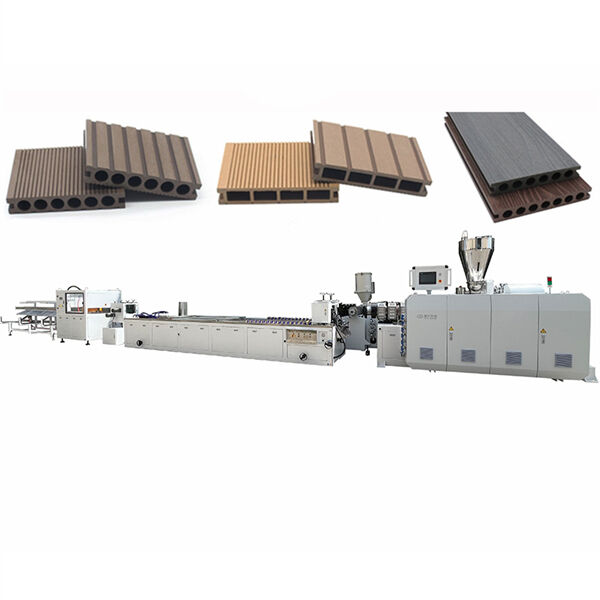

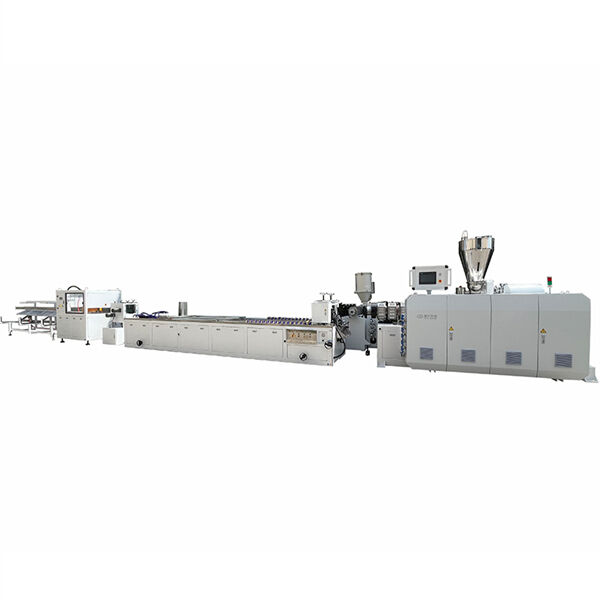

Mēs piedāvājam plastmasas pulvera mīņas mašīnas, kas ir pielāgotas attiecībā uz izmēru, krāsu un automatizāciju. Mēs varam arī pielāgot formu saskaņā ar galīgo produktu. No Zhangjiagang Xinhe Machinery līdz Jiangsu Xinhe Intelligent Equipment Co., Ltd., mēs esam kļuvuši par vienu no desmit lielākajiem ķīniešu plastmasas ekstrūzijas līnijas ražotājiem.

Jiangsu Xinhe ietver stingrus standartus saistībā ar dzelzs platumu un materiāliem un nodrošina drošības pasākumus visos riskanta elementiem plastmasas pulvera mīņas mašīnās. Mūsu ražošanas līnijas piedāvā garu dienestu ilgumu, zemas kļūdu biežumus un stabulu, efektīvu ražošanu. Daudzi mūsu klienti jau vairāk nekā 8 gadus izmanto savas mašīnas.

Mēs varam piemērot masīnas konfigurāciju atbilstoši mūsu klientu noteiktiem prasībām. Fabrikas tiešie pārdošanas, augstas kvalitātes produkts un pilnīgs pēcpārdošanas serviss. Mūsu masīnas ir paredzētas darboties vairāk nekā plastmasas pulverizācijas masīna un tās tiek augsti novērtētas klientiem no Vjetnamas, Indonēzijas, Saudijas Arābijas, Dienvidāfrikas, Bolīvijas un dažādām citām reģionu.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights Reserved