Ora ci sono più ordini per le schede PVC Xinhe, quindi in questo momento abbiamo bisogno di buone macchine per produrne delle identiche. macchina estrusore per fogli in plastica vengono create da cui si costruiscono diverse cose, come il PVC e i materiali pubblicitari, quindi devi ottenere una scheda di alta qualità. Quindi cosa fa Xinhe: Macchine che producono schede PVC in modo più innovativo ed efficiente rispetto al passato.

Un po' di tempo fa, tutto veniva realizzato manualmente prima dell'esistenza delle macchine per il processo. Ma il processo era difficoltoso, con un gran numero di passaggi manuali e quindi molto lento e soggetto a errori. Alcune delle tavole venivano anche tagliate in modo errato completamente per sbaglio, a causa di un errore da parte degli operai o di un passaggio saltato nel processo. Le sue macchine automatizzate gestiscono quasi tutto, dopotutto. Le macchine si occupano di tutto, dalla consegna dei materiali grezzi all'imballaggio del prodotto finito. Questo processo totale richiede molto meno tempo e ci sono meno errori, quindi produciamo tavole migliori. Aumenta anche la sicurezza dei suoi lavoratori, poiché ci sono meno probabilità di incidenti.

Ci sono così tanti casi d'uso fantastici per queste macchine Xinhe… Lo scopo principale è quello di accelerare il processo di produzione. Come questa macchina che può fare esattamente lo stesso lavoro in una frazione del tempo necessario per realizzare ogni singola scheda manualmente, una alla volta. Questa velocità aiuta anche a ridurre i costi di produzione delle schede, poiché sono necessari meno operai per farlo. La maggior parte di quel lavoro può essere svolto dalle macchine, il che significa che hai bisogno di meno persone sulla linea di produzione. Aiuta le aziende a ridurre i costi del lavoro.

La macchina per la produzione di porte contribuiscono anche alla qualità delle schede. Sono in grado di tagliare i materiali con grande precisione, lasciando meno sprechi e imperfezioni nel prodotto finale. Non risparmia solo materiali, ma garantisce anche che i tuoi clienti ricevano la migliore qualità.

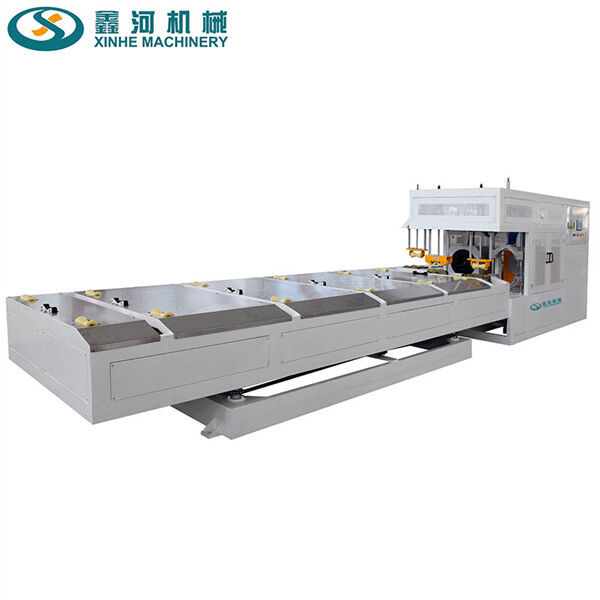

Xinhe ti fornisce il nuovo sistema di fabbricazione delle macchine PVC della prossima generazione! Tagliamo le schede PVC con il nostro CNC e poi le modelliamo in qualsiasi dimensione e forma utilizzando i nostri macchina per la produzione di telai per porte . Con questo, Babolat può anche realizzare finiture diverse come lucide e opache per soddisfare le preferenze dei clienti. Hai bisogno di avere questa gamma perché alcune persone potrebbero effettivamente desiderare che abbia quell'aspetto.

Xinhe produce macchine facili da usare che migliorano la durata del loro utilizzo. Queste hanno parti di buona qualità, il che le aiuta a resistere a carichi di lavoro elevati senza che si rompa alcuna parte. Macchina estrusore per tubi in plastica , soprattutto quando prodotto da Ford, è essenzialmente costruito per essere un'auto di produzione di massa in grado di funzionare quasi tutto il giorno con una manutenzione minima. Nel caso di macchine in vendita, potrai anche usufruire di software facili da usare inclusi con esse. Ciò garantisce che siano abbastanza semplici da utilizzare anche per un lavoratore inesperto senza la necessità di un addestramento sostanziale che le aziende preferiscono non fornire ai nuovi assunti, risparmiando tempo e denaro.

Il panorama commerciale sfrutta la qualità superiore di Xinhe produttori di macchine estrusore per plastica . In un certo senso, le aziende che hanno macchine per produrre molte schede velocemente non perdono le loro vendite/profitti. La precisione e la velocità con cui le aziende producono schede è ciò che le aiuta a competere meglio con i concorrenti.

A Jiangsu Xinhe aderiamo a standard rigorosi riguardo lo spessore e i materiali dell'acciaio delle macchine e forniamo misure di sicurezza per le aree a rischio nelle nostre linee di produzione di macchine per tavole in PVC. Offriamo una lunga durata con bassi tassi di guasto e una produzione stabile ed efficiente. Molti dei nostri clienti utilizzano le loro macchine da più di 8 anni.

Pre-Vendita: Il nostro personale di vendita con più di cinque anni di esperienza ti fornirà la migliore configurazione della macchina per la produzione di pannelli in PVC. Offriamo un servizio 24 ore al giorno ai nostri clienti e proponiamo visite video della fabbrica. In-Vendita: Possiamo fornire video della produzione, dal acciaio grezzo al prodotto finito, nonché video della produzione su tutta la linea. Dopo-Vendita: I nostri ingegneri offrono supporto sul campo per i costi e assistenza tecnica a vita tramite video, dalle materie prime al prodotto finito.

Le nostre macchine sono configurate per soddisfare i requisiti del cliente. Forniamo vendite dirette dalla fabbrica di prodotti premium e un ampio servizio post-vendita. Le nostre macchine hanno una durata superiore agli 8 anni ed sono molto apprezzate dai clienti del Vietnam, Indonesia, Sudafrica, Bolivia e molti altri paesi.

Offriamo macchine personalizzate in termini di dimensioni, colore e automazione. Gli stampi sono personalizzabili in base all'aspetto atteso del prodotto finale. Siamo evoluti dalla macchina per la produzione di pannelli in PVC ed oggi siamo diventati una delle dieci principali linee di estrusione cinesi in plastica.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights Reserved