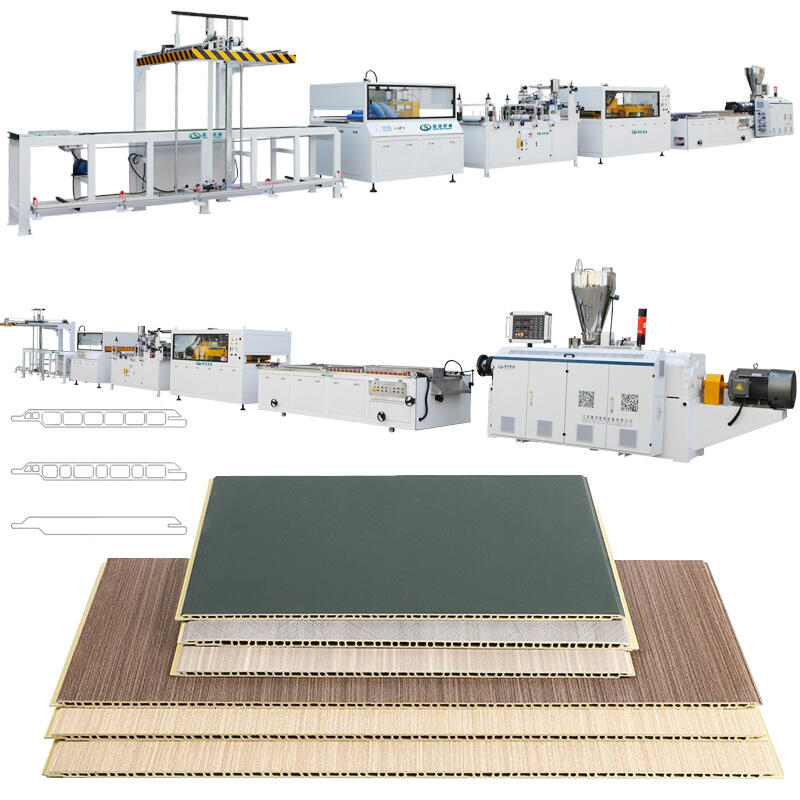

An additional aspect of this particular project is that all these panels are going to make up wall panels, therefore it was crucial that each panel had the same quality and looked the same as all others. These issues can happen when building a wall if all the panels are not the same. Enter the Xinhe infrared correction tool The special tool will help to ensure that each panel is perfect and meets the necessary criteria. In this post, I will be giving a very good review to explain why the Xinhe infrared correct tool is so critical when it comes to reliable panel wall making.

Better Quality Through Infrared Correction

Xinhe infrared correction tool is applied to the machine mainly to improve the appearance of wall panel. Subsequently the workers can inspect each panel carefully and rectify any issues before they are completed. The infrared correction tool examines each panel, scanning it for squares on end that are not square or straight or rectangles that have developed curves. With this tool, workers can ensure the panels are of outstanding quality ensuring they meet strict demands that customers expect. This operation is crucial, as it reduces the risk of trouble during handling and knocks in at a later stage.

Aiding Workers Produce Panels Quicker

The infrared correction tool of Xinhe also has a very important function, to speed up the worker panel making. In a production line, time is money, so with the right infrared-correction it is possible to rapidly correct sheet sizes. This tool monitors the temperature of the machines Wpc wall panel being made at all times and is responsible to keep it under control gang box manufacturers This is very important to maintain the shape, and size of the panels. So, as long as the temperature is right, workers can continue making those panels without pause. This helps us run the production process in an even more smooth and effective way, awesome for everyone.

Reducing Mistakes and Waste

In addition, the said ability of the correction tool may be integrated to decrease faults in generating boards via the use of Xinhe infrared. Mistakes are easily made if things aren't fixed and controlled well then you end up having to throw panels away. This is going to either waste money or more importantly waste materials. But because of this infrared correction tool most (if not all) of these errors can be avoided. The tool helps to catch problems early, saving materials and money, keeping the whole process efficient. In practical terms, it allows detail-oriented organizations to spend less money on waste and more on delivering quality products.

Not Changing Panels During Quick Production

The key to producing wall panels quickly and efficiently is controlling your inventory by keeping everything the same throughout the process. Xinhe infrared correction tool Temperature and humidity control device for Xinhe Home Walls need to be plumb in order for the Wpc wall panel machine to work properly and stay true. It helps to keep the humidity levels in check so that all panels are able to keep their size and same shape. It is a make or breaks factor in making wall panels of high-quality, type of all panels which stand uniformly well together.

The Importance of Infrared Correction for Restoring Great Wall Panels

To put it simply, the Xinhe infrared correction tool is indispensable for creating good wall panels that satisfy clients. It has revolutionized how panels are made in a good way. This makes for better panels with future cost savings. Xinhe is known to thrive on finding the latest and most creative techniques in order to enhance their quality of products and even offer the best resources for clients that are available for any job.

But we have the Xinhe infrared correction tool, With it every panel could be produced perfectly. Making all same as before and qualified from our customers. Whether it is for checking quality to measure correctly, making production time faster, reducing mistakes or keeping everything consistent, the Xinhe infrared correction tool proves to be a very useful welcome addition to anyone involved in making wall panels. The tool manages design functions to not only make sure they work, but look good as well–creating a product that customers actually want.

EN

EN

AR

AR

BG

BG

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MK

MK

HY

HY

AZ

AZ

UR

UR

BN

BN

LA

LA

NE

NE

MY

MY

KK

KK

UZ

UZ