You are in the right place to learn how to save costs of manufacturing WPC door panels. Infact WPC or Wood Polymer Composite is not only term but very beneficial new material, that purposes various advantages. It is a type of commodity that we use to produce doors and many other part objects of our daily life. Broadly speaking as we report so many stuff but when discuss over the production of WPC panel doors, there are some steps that needs to be followed. These are tasks such as melting the material and smoothing it out so that everything runs smoothly and appears aesthetically appealing.

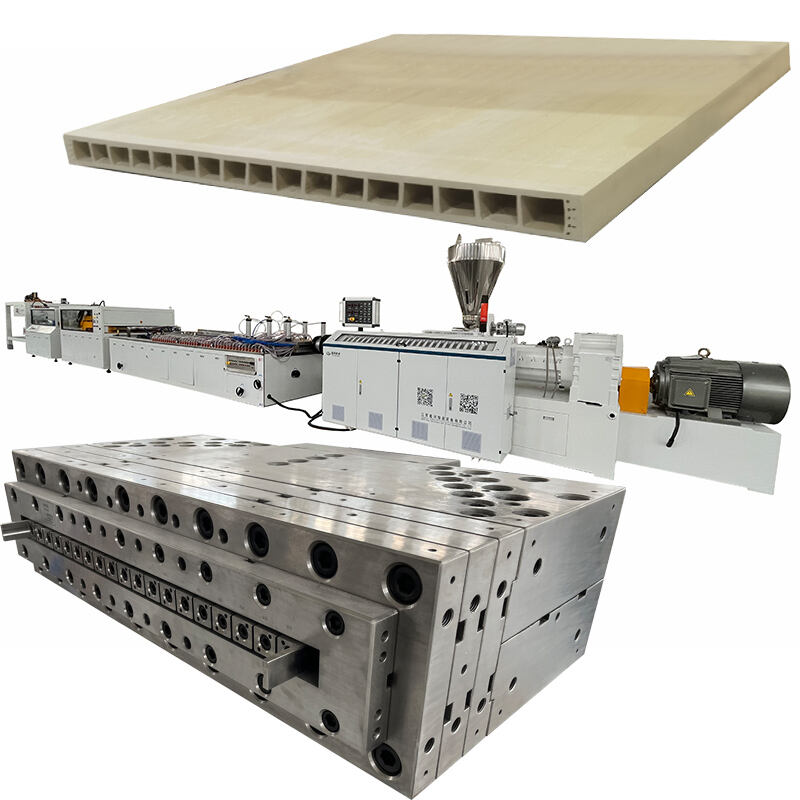

Having the right tools is key to make this process as easy and smooth as possible. The first one item of the most needed tools to start Any cotton project, called extrusion lines. Source — Door panel forming machine (Heating and moulding of WPC material for door panels) The extrusion line is used to produce and verify that the material can be properly shaped for use.

How to Choose An Extrusion Line in Xinhe

Xinhe as brand makes very good Plastic Board Machine for WPC door panel production so, choosing the extrusion line is perfect. You need to consider a few important aspects when you are selecting an extrusion line. Think of the size of a production line. You should also consider the type of WPC material being used as well, and how much money you want to invest in tools.

She have various types extrusion lines, can suitable for different demands and budgets. For an example, if you have a small production line the JWM series could be perfect for you. It is efficient and meant for smaller use. SJMS series shall apply if your production line is much larger. This series is created to larger operations and will be able to sort out more quantity of material during a time, before saving you amount of oakley fives squared sunglasses running for them.

WPC Door Panel Production Cost Saving

If you want more profit, saving money on making WPC door panels to a great extent is necessary. Protect the planet like consuming reasonable raw materials, for example. Xinhe has extrusion lines for varied kinds of WPC materials, including PVC and PE. Different materials allow you to practice your skills by making items from whatever material fits the project while saving costs.

Another method of cost savings is through minimising wastage during the production process. Waste is simply defined as materials that are thrown away in a not proper use. These systems help Xinhe’s extrusion lines to produce less waste and ensure that the quality of products is at a high level. This in turn means you will need to re-work errors less which all goes towards processing faster and higher-quality.

Increase the Performance OF Your WPC Door Panel Production

WPC door panel is a product, to do better in the production of WPC door you have to find ways or methods that less costly effective use for your resources. Using automatic work Plastic Pipe Machine is one way to do this Xinhe extrusion lines with automatic feeding and control systems And this means the machines can do a lot of it themselves, which in turn reduces your leg work.

You could also reduce downtime to improve your process. Downtime, on the other hand, is when Plastic Profile Machine are not working because they need repair or maintenance. Xinhe Shape Moulding Machine Extrusion Lines Specifically Design Convenient for Replacing Parts and Fast Repair of Equipment With it, you do not need to spend that much in mending problems; thus, it is also possible for your production line to keep up with its flow.

How to Make WPC Door Panels Smartly

The best way is to use right fully tools integrated in the process so as to make WPC door panel smartly. This is where extrusion lines from Xinhe can help, offering a flexible and cost-effective solution for producing WPC door panels. Having the best tools at your disposal and consistently processes in place will make you work much more comfortably, get a good job done.

XINHE offers extrusion lines by which you can make production easier, save money and improve your productive line with. This will enable you to develop superior products besides keeping your margins of profit intact. Staying true to optimal efficiency in your manufacturing process equates to reaching those goals and ensuring that your business is a successful entitygetProperty.

To sum it up, your selection of high-quality WPC door panel production must start with the right extrusion line. There are many extrusion lines in xinhe which can help you save costs, better processing effect works. Xinhe Extrusion Line makes sure to not only meet — but exceed, your production goals in the wisest and most non-expensive way possible for a successful budget-wise manufacturing operation.

EN

EN

AR

AR

BG

BG

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MK

MK

HY

HY

AZ

AZ

UR

UR

BN

BN

LA

LA

NE

NE

MY

MY

KK

KK

UZ

UZ