Omdat dit sterk, duurzaam en omgewingsvriendelik is, is dit onder die gewilde tipes deure in China. Dit is ook die rede waarom hierdie deur veral minder houtpoeder gebruik as ander, maar het jy ooit daaroor gedink? Dit gaan nie net oor hoe goed die deure is of hoeveel houtpoeder beskikbaar is nie. Dit het baie meer te doen met hoe die deure gemaak word en die prosesse wat vir hul vervaardiging gebruik word. Die artikel bespreek die verminderde gebruik van houtpoeder in die vervaardiging van Wpc deur maak masjien en hoe nuwe tegnologie help aanbieders om hierdie doelwit te bereik.

Waarom gebruik WPC-deure minder houtpoeder?

Wat beteken WPC – WPC is kort vir hout-plastiek samestelling. Produkte word ontwikkel deur gebruik te maak van drie basiese komponente: houtpoeder, plastiek en ander spesiale materiaalle wat die produk doeltreffender maak. Die houtpoeder word gewoonlik ingesamel vanaf afvalhout van fabriekte wat hout tot meubels of ander produkte zaag. Eigenlik, in vergelyking met WPC-deure oor die wêreld, gebruik WPC-deure in China minder houtpoeder, wat ook 'n bietjie verbazend is.

Die primêre rede hiervoor is die behoefte aan goeie kwaliteit houtpoeder. Houtpoeder kan goed gebruik word as dit goed behandeld word tydens die vervaardiging van WPC. As die proses wat in die vervaardiging van die houtpoeder ingegaan nie reg behandel word nie, kan daar probleme in die eindproduk wees. Nou, die kwaliteit van die houtpoeder in China is soortgroot verskillend, en baie maatskappye is nie in staat om elke keer soos 'n hoë-kwaliteit houtpoeder te skep nie.

'n Tweede rede vir die gebruik van minder houtpoeder is dat houtpoeder duur kan wees om te vervoer en te prosesseer. Houtpoeder is 'n byprodukt, maar die produk het steeds vervoerkoste om dit van punt A na punt B te bring, en tyd om die hout voor te berei om dit bruikbaar te maak. Om koste te bespar en wins te maksimeer, gebruik baie maatskappye minder houtpoeder en meer plastiek in hul WPC. Hierdie keuse laat hulle bespare terwyl hulle steeds robuuste produkte vervaardig.

Hoe Tegnologie Help

Tog speel nuwe tegnologie 'n belangrike rol in die vervaardiging van beter WPC-produkte deur minder houtpoeder te gebruik. Byvoorbeeld, sommige vervaardigers maak gebruik van 'n tegniek wat ko-ekstrusie genoem word. Verskillende tipes plastiek word vir verskillende lae in die WPC-produk gebruik. Dit sal maatskappye help om nie te veel houtpoeder te gebruik nie en gee hulle die vermoë om robuuste en duurhape deure met hierdie proses te produseer. Dit is ook 'n uitstekende benadering vir 'n balans van die toegepaste materiaal vir eindproduk-kwaliteit.

Behalwe data-drywe co-ekstrusie, laat tegnologie vervaardigers toe om additiewe te kombineer. Hierdie additiewe kan verskeie eienskappe van die WPC-materiaal verbeter. Byvoorbeeld, hulle kan die sterkte, lewensduur en estetiese aantreklikheid van die deure verhoog. Met hierdie additiewe kan vervaardigers minder houtpoeder gebruik sonder om die kwaliteit wat hul klante eis, op teoffer.

Waarom smeringsmiddel gebruik by WPC-deure? Waarom gebruik jy so min houtpoeder?

Dus waarom het WPC-deure in China so min houtpoeder? Uiteindelik kom dit neer op koste, kwaliteit en hoeveel tegnologie vervaardigers geïmplementeer het. Dit kon die begin wees van 'n reeks nuwe ontwikkelings wat lei tot die verhoogde gebruik van 'n bietjie meer houtpoeder in die produksie van WPC-produkte soos maatskappye nuwe en verbeterde produksietechnieke ontdek wat steeds minder houtpoeder gebruik. Maar op hierdie stadium is die sleutel om minder houtpoeder te gebruik om die deure sterk en betaalbaar te hou.

WPC Deur Maak Proses

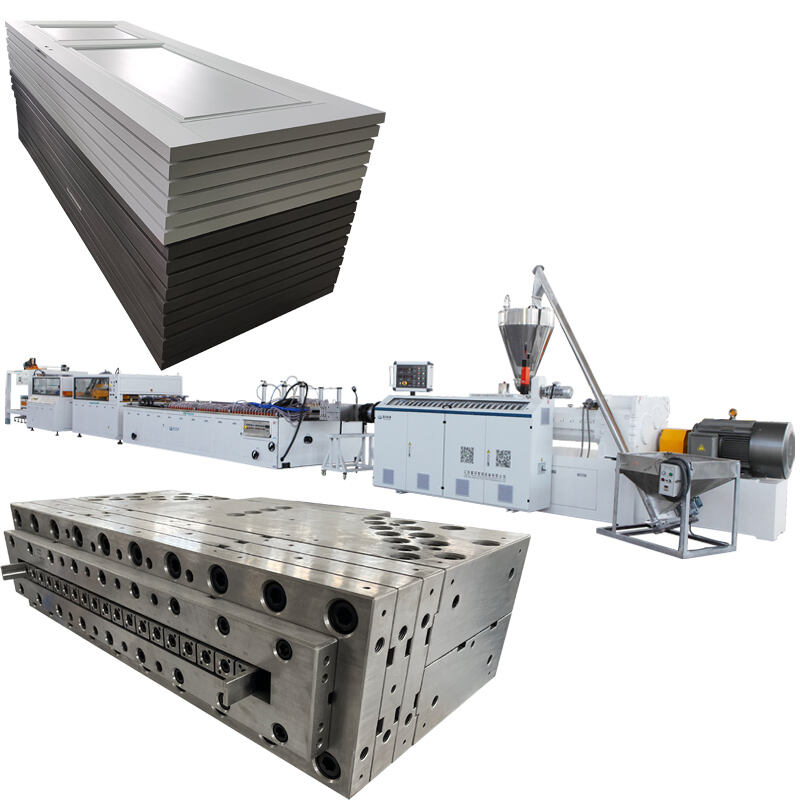

Die spel van maak Wpc deurmeganisme is een baie komplekse een. Dit word gedoen deur houtpoeder en plastiek te meng, deur middel van masjiene wat ontwerp is vir die beste mengsel van die twee mediums. Aangesien dit 'n baie komplekse proses is, beteken dit dat maatskappye moeite kan ondervind om konsekwente resultate te bereik wanneer hul houtpoeder byvoeg. Dit verduidelik waarom baie Chinese vervaardigers liever minder houtpoeder gebruik. Hierdie klein stap word genomen om die kans te verminder dat deure van verskillende kwaliteit gemaak word en om seker te stel dat hul produk aan die klant se verwagtinge voldoen.

In gevolg hiervan, word die persentasie houtpoeder in China-gemaakte WPC-deure bepaal deur die hoofrolspelers koste, kwaliteit en tegnologiese weergawe. Met vooruitgang in tegnologie kan die vlak van houtpoeder hoër wees in WPC-deure in die toekoms. Maar vir nou het China WPC-deure geskep wat die taak doen met minder houtpoeder. Hierdie manier van werk laat hulle toe om seker te stel dat hul produksie dieselfde kwaliteit is asook om hul goederye te verfyn. Xinhe is toegewyd om 'n duurzaam en omgewingsbeskermende produk te produseer. Wpc deurvervaardigingsmasjien met hoë prestasie, terwyl hulle voortgaan om te innoveer om hul produksieproses te verbeter.

EN

EN AR

AR

BG

BG

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MK

MK

HY

HY

AZ

AZ

UR

UR

BN

BN

LA

LA

NE

NE

MY

MY

KK

KK

UZ

UZ